|

|

|

#1 |

|

Junior Member

Join Date: August 30, 2015

Posts: 5

|

Improper sized brass

I am new to reloading and sized and primed 200 rounds of .223. Proceeded to charge and seat bullets on 100 of these and about 70% of these are hard to get the bolt to close. Should i shoot the hard to close rounds Or will they damage my gun. And how do i resize the other 100 that have been primed safely. All opinions will be helpful. Thanks

|

|

|

|

|

#2 |

|

Senior Member

Join Date: December 11, 2012

Posts: 527

|

Where did you get your brass?

Are your dies full length resizing dies? |

|

|

|

|

#3 |

|

Junior Member

Join Date: August 30, 2015

Posts: 5

|

All of it was once shot brass from multiple companies. And they are lee full length dies. I know how i messed up the sizeing procedure. I just want to know what to do with the finished rounds and primed brass

|

|

|

|

|

#4 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,898

|

If it's a bolt gun (not a gas gun), go ahead and shoot them. **

For the other cases, simply pull the depriming pin out of the expander (leaving the expander ball itself) and resize them to spec. For now, do a full resize by screwing the resizing die in ~1/8 turn past full contact w/ the ram **If it's a gas gun (e.g., an AR) pull the bullet and resize w/o depriming as suggested above. |

|

|

|

|

#5 |

|

Junior Member

Join Date: August 30, 2015

Posts: 5

|

Yea i messed up I did that with my first 50. But then talked to a family member that told me to back off the die instead...Mistake. Thank you

|

|

|

|

|

#6 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Calfpuller,

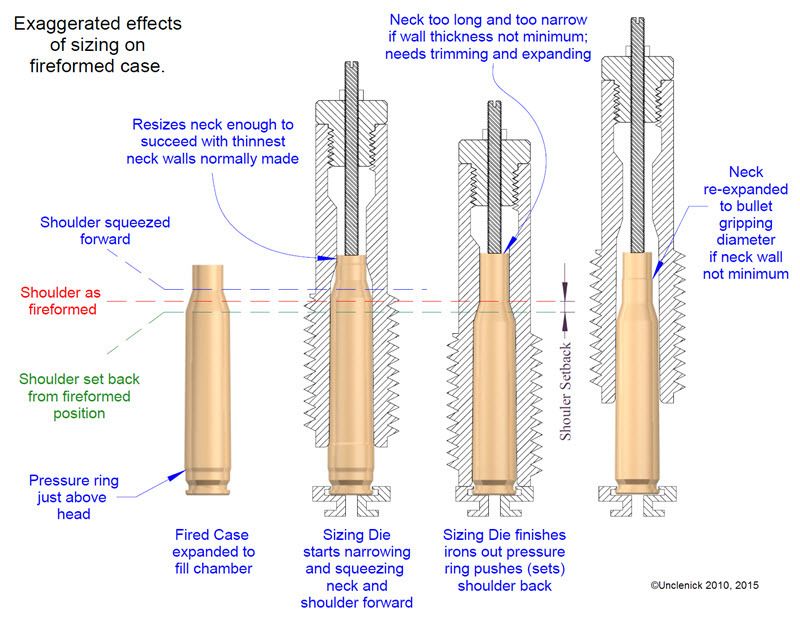

A die sizes as follows:  All these images are relative to the shell holder position, so the shell holder stays put and the die comes down so that you can compare the brass lengths. Notice how, in the first sizing drawing, second from left, the brass, which has been fattened by expanding to fill a chamber, first gets squeezed longer because it gets narrowed first by the die, and that squeezed brass has to go somewhere. When you bring the die down far enough (second sizing step, third from left), it is then that the shoulder is pushed back where it is supposed to be, and the excess brass then flows into the neck. It is that last step that causes you to need to trim brass from time to time. People who use neck sizing only almost never need to trim brass. Also, in general, once-fired brass is military brass that has often been run through the loose chamber of a fully automatic military weapon. This stuff is often fatter than normal and longer than normal, having been stretched by hard extraction. So there are times when even a properly adjusted standard sizing die can't squeeze them back past their spring threshold. On those occasions, you can use a separate small base die which squeezes them down a bit extra, or you can try sizing the two or three times, letting the brass rest up inside the die for five seconds each time, which often gets another couple of thousandths of shoulder setback. Board member F. Guffey has a simple trick, which is he cuts out a piece of shim stock so it slips between the head of the case and the bottom of its slot in the shell holder. You can usually fit 0.005" shim stock in there, and often something even thicker. By raising the head up in the shell holder, you let the sizing die shorten it that much more during resizing. As to your current predicament, Mehavey's suggestion is right with most dies, because they mostly have a separate expander ball held in place by a decapping pin chuck. Your Lee, however, has them all as one piece. So if you want to use the Lee die, you will want to remove the decapper/expander rod, size the brass again, perhaps using the shim stock, and afterward put the rod back in place and run the brass up onto the die just far enough to expand the mouth of the case, but not far enough to decap the live primer. It's a good idea, when manipulating brass with a live primer, to be wearing safety glasses and hearing protection. They can be surprisingly loud and throw a shower of sparks.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle Last edited by Unclenick; August 31, 2015 at 01:30 PM. Reason: typo fix |

|

|

|

|

#7 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,898

|

Thx UncleNick

(I missed the OP's Lee die spec) |

|

|

|

|

#8 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

"...will they damage my gun..." Not unless the powder charge is excessive.

Option one is to shoot 'em assuming you can get the bolt to close. Firing will expand 'em to the chamber dimension and you start over. Option two is to pull 'em, remove the decapping pin for the die and resize 'em. Option one would be way better than pulling 200 rounds. "All of it was once shot brass from multiple companies." Isn't milsurp.

__________________

Spelling and grammar count! |

|

|

|

|

#9 |

|

Junior Member

Join Date: August 30, 2015

Posts: 5

|

By once fired brass i should have clarified that this was ammo I had bought new shot, and then saved the brass to reload. Not milsurp but hunting rounds or fmj's for plinking

|

|

|

|

|

#10 |

|

Senior Member

Join Date: June 9, 2010

Location: NEPA

Posts: 909

|

There are several reasons why they might not chamber:

1. Shoulder not set back far enough. 2. Bullet AOL too long and the bullet is being pushed into the lands of the barrel. I would smoke some of the bullets, chamber them and see if the lands leave any marks on the bullets. You should only set the shoulders back a little bit. You can check this be sizing one all of the way down on the shell holder and then seeing if it will chamber. Then back out the die and try another one. You will reach a point where it will not chamber. At that point the die has been backed out too much. Turn back in and try again. |

|

|

|

|

#11 | |

|

Senior Member

Join Date: October 23, 2005

Location: US

Posts: 3,657

|

Quote:

Or your sizing die may not be set correctly. Also check the length of your brass. |

|

|

|

|

|

#12 |

|

Senior Member

Join Date: January 6, 2011

Location: Thornton, Texas

Posts: 3,998

|

Easiest approach, which I've done quite a bit over the years, is to buy a Redding Body Die in your caliber and just resize the loaded rounds. The die is inexpensive.

Some years back I sold my Ruger 260 (roomy chamber) and replaced it with a new Tikka with a custom barrel (snug chamber). I had a lot of ammo and didn't want to pull the bullets. I took the Body Die and screwed it down till I reached the shoulders of a loaded round that was raised all the way with the press ram, lowered the ram, screwed the die in a bit, then raised the ram and slightly resized the round. If that didn't allow the round to chamber in the rifle, I screwed the die in a touch more and tried again till I got a round that would chamber. Easy and quick. Did the same with my 223 ammo for this years new barrel. |

|

|

|

|

#13 |

|

Junior Member

Join Date: August 30, 2015

Posts: 5

|

i will look into the body die, overall length on 50 is 2.20 and 2.25 well under the lee dies max length in the directions. I know that i had the dies set wrong now. Just have to undo the damage. Thanks for all the help

|

|

|

|

|

#14 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

Calfpuller,

Since the brass came out of your chamber, it is most likely you just got the die out too far and actually lengthened the head to shoulder dimension rather than pushing it back, as my illustration shows. The much less likely possibility is your chamber being extremely off-axis with the bore, so your heads are fire-formed out of square and then don't fit back in when the headstamp isn't oriented the same way it was at the previous firing. To check for this you decap the cases without sizing them, then line them up on a flat surface to see if all the case mouths line up or if they tilt randomly out of line. The COL is probably OK, but you should check for engraving marks as suggested, just the same. It's how far the bullet ogive is sticking out and not the COL to the nose of the bullet that matters. Below is an illustration of two bullets the exact same distance off the lands, but look how different the COL's are. This is why you want to double-check.  The Body Die is a great tool, but unless you get a small base version, it won't necessarily do anything you can't do with your standard die, except that the standard die will resize the neck again when you do it, while the body die will leave the neck alone. If you were going to do this all the time, I'd say getting that die was worth it to extend case life, but I expect you're planning to avoid a repeat of this issue. Where the body die really shines, IMHO, is for use in conjunction with the Lee Collet Die. The latter sizes a neck without any runout. The former handles sizing the body without disturbing the neck. They were made for each other, albeit not intentionally.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#15 |

|

Senior Member

Join Date: January 11, 2015

Posts: 330

|

Check the length of the cases as well. I personally believe that the shoulder being set back to far is not the problem. As you said, you messed up by backing the die out. check the length of the brass before loading and, trim if necessary. God Bless

|

|

|

|

|

#16 |

|

Senior Member

Join Date: January 6, 2011

Location: Thornton, Texas

Posts: 3,998

|

I mentioned the Body Die, and I really do think it's the fastest and easiest way to get from where you are to where you want to be. That said, the first thing I'd do is get a factory round and measure in all directions and compare to your reloads. That's what I finally had to do with my new 223 barrel. No matter WHAT I did, my new loads with new Lapua brass would NOT chamber. Made me crazy. I'm not new at this reloading business, but I had never run into a problem I couldn't solve. Well, I knew the gunsmith had fired factory rounds in it. I had no factory rounds. Haven't shot a factory round this century. Borrowed one from a neighbor. It chambered. I measured it every way possible. It was the case necks not fitting into a tight match chamber. I hadn't asked for that tight a chamber, but that's what I got. The new Lapua brass had relatively thick case neck walls and stretch it with a bullet and it wouldn't fit in the chamber. I turned the necks and all was well, but I finally took it back to the smith to open the chamber to SAAMI specs. Problem solved. Finally.

So measure. Then get the body die and shrink the case just enough. |

|

|

|

|

#17 |

|

Senior Member

Join Date: August 25, 2011

Location: California

Posts: 776

|

In my experience and laziness as a beginner my handloads of 223 for the AR using once fired brass jammed royally. The once fired brass, bottle neck cases, will grow/lengthen and must be trimmed.

Last edited by 745SW; September 1, 2015 at 12:03 AM. |

|

|

|

|

#18 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

The body die only idea is to bump the shoulder back on a loaded cartridge , YES/NO ? You can't do that with any standard FL die . I would not get a body die though . I'd get the Redding type S Full length bushing die . Reason why is if you don't use/put a bushing in the die it works as a body die only . You then will always have the option to buy some bushings and have one of the best FL sizing dies out there .

You will need to remove the decapper/expander rod to use the bushing die as a body die to bump the shoulder of a loaded cartridge . http://www.midwayusa.com/product/676...ProductFinding Quote:

F. Guffey has a simple trick, which is he cuts out a piece of shim stock so it slips between the head of the case and the bottom of its slot in the shell holder.

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; September 2, 2015 at 12:00 AM. |

|

|

|

|

|

#19 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

A reloader should be able to determine if the case was sized before they lower the ram. There are times the case has more resistance to sizing than the press can overcome. They have choices, decrease the resistance of the case or increase the presses ability to overcome resistance. F. Guffey Last edited by F. Guffey; September 1, 2015 at 07:27 AM. Reason: change . to ? |

|

|

|

|

|

#20 |

|

Senior Member

Join Date: January 6, 2011

Location: Thornton, Texas

Posts: 3,998

|

Metal God, the suggestion to buy a Redding Type S FL Bushing Die and then use it without the bushing and other guts is a good one for resizing loaded rounds, but the Body Die is a cheaper way to go, and it will FL resize the case (except for the neck). Depending on the caliber, I have both. For the 260, for instance, I already had a FL Die that I liked, so I wanted to go with the least expensive way to resize the rounds. That was the Body Die.

In some calibers I use the Lee Collet Die (neck size only), so the Body Die is mostly just used to bump the shoulder when needed. But sometimes other issues arise. I loaded up some 223 rounds the other day, ones where the cases had been sized with the Lee Collet Die. I didn't notice that the Lee Die, needing a bit of lube, had jammed up and rolled the shoulders of some cases slightly, which would now not chamber. I dug out the Body Die, and in just a few minutes had all cases back to 'normal'. So it's good to have one at times. It's cheap, relatively speaking. |

|

|

|

|

#21 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

F. Guffey |

|

|

|

|

|

#22 |

|

Junior Member

Join Date: August 31, 2015

Posts: 7

|

Calfpuller,

Yea i messed up I did that with my first 50. But then talked to a family member that told me to back off the die instead...Mistake. Thank you Well, its not at all a mistake to do this. Its how I reload for all my rifles to include all six of my AR's. The problem is that whoever suggested this didn't fully explain what is required when this procedure is to be used. First a little background on how a sizer die works the brass case. As the case is being forced into the die the case wall will be the first part of the case to be squished to a smaller diameter thus pushing the shoulder of the case farther from the head. The mid point on the shoulder (the point at which head space is measured to the case head) is lengthened. Then as the case is further pushed the shoulder makes contact with the die and brass from the entire case is pushed into the neck. Also the head space measurement then becomes shorter until the case is fully inserted into the die. A tool you will need is a head space gauge (Hornady sells one) that attaches to your caliper so that you can measure the distance from the mid point on the shoulder to the case head. (Head space) 1. Buy a box of ammo and shoot in said gun. 2. Using a head space gauge measure the fired brass and put that measurement in your reloading log. 3. Decap and clean your brass. 4. Lube up a case and put it in the press and pull the handle all the way down. 5. Screw sizing die down until contact with case is made. 6. lower the case and turn die 1/4 turn then insert brass into the die. 7. Remove brass and measure head space. (Repeat this lubing case occasionally until you see the neck get to the point where it becomes fully sized. 8. Once the case looks like the shoulder will make contact with the die use very small movement turning the die. 9. Its very important to measure the head space between each insertion of the case into the die. 10. Once the head space measurement is .001" shorter than the original fired case measurement you run the case back into the die and tighten the jam nut and lock it. 11. Take the next case and run fully into the die and verify that the die is accurately set to .001" under the fired case measurement. Thats it your done. Size 5 cases and cycle them through the gun to verify and load away. The benefit of this procedure for sizing is that if you trim your brass to the minimum trim length it won't grow much if any between firings. Trimming brass sucks if your doing it by hand and 2000 pieces of 223 is hell. Plus your brass will last much longer because you will not be working it as much. Hope this helps. As for your already loaded brass. I would just pull the bullets, remove the decap pin from the sizer (Leave the expander ball) and resize the brass and load em up again. |

|

|

|

|

#23 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Oh I want to but I'm not . Maybe Mr Guffey will say something

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#24 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .  HAHAHAHAHA , Yea mine didn't chamber either

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; September 1, 2015 at 11:57 PM. |

|

|

|

|

|

#25 |

|

Senior Member

Join Date: October 23, 2005

Location: US

Posts: 3,657

|

Madgunner I do something similar to your 11 step process, but my method is a little more hasty and improvised. I will say that your method is probably easier for an AR (although I would probably give .002-.003" clearance in a semi, just me personally), but here's what I do for my bolt gun. Feel free to skip 1a and 1b if you don't neck size at all, although I think neck sizing after the first firing gives the brass a little extra stretch and helps to make it good and tight in the chamber so you can find that optimal fit in the later steps. Plus I like to think I get an extra firing or two out of my crappy Federal brass because I don't full length size EVERY time. I've found accuracy to be equal between the two if I do my part correctly.

1: Fire a factory round 1a: For those who neck size only at times, I neck size with a Lee Collet die per the instructions provided. 1b: Fire again. If the round fits a little too tight it's time for a full length size, most of the time I don't full length size until the third firing. 2: Screw the full length die until it touches the shell holder. 3: Lube the brass. 4: Size one round and then try to chamber the sized brass. This is more of a control, and will still be tight because the shoulder hasn't been touched yet. 5: Screw in the sizing die in increments and keep sizing until you can tell that the bolt closes noticeably easier. It's usually about 1/8" of a turn further in after making contact with the shell holder, and I can usually see light marks on the shoulder where the shoulder has been bumped slightly. 6: If step 5 was done properly (i.e. you adjusted in small increments), you probably need to adjust in a tiny bit more unless you're okay with putting a good bit of pressure on the bolt to close. 7: Once you feel the point that you still have a little more resistance than a factory round on bolt close (noticeable, but not annoyingly so), you are probably at optimal length for your gun. This was my experience 8: Mark your die position. I loc-tited the nut on my die, then mark the plate and die nut with an engraver. Or if you have tons of plates then just leave it. I've found that I can unscrew the die from the plate, then return it again and have repeatable results. 9: I always throw out the piece of test brass. There are a number of reasons why, but my biggest concern is run-out. |

|

|

|

|

|