|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Search | Today's Posts | Mark Forums Read |

|

|

|

Thread Tools | Search this Thread |

|

|

#51 | |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,883

|

Quote:

"Squirt some CLP into the port and keep firing!" yelled the Team Leader. Words that still ring in my head.

|

|

|

|

|

|

#52 | ||

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

Did you clap your hands for Tinkerbell? “I believe in fairies, I do, I do, I believe in fairies, I do, I do.....”

__________________

If I'm not shooting, I'm reloading. |

||

|

|

|

|

#53 |

|

Junior member

Join Date: May 8, 2013

Posts: 81

|

..who thinks youre supposed to "squirt" oil all up in the chamber. let him do it and let him learn for him self.

Last edited by JohnKSa; June 14, 2013 at 08:44 PM. Reason: Over the top. |

|

|

|

|

#54 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,883

|

Could you reference who in this thread advised "....'squirt' oil all up in the chamber." ?

Inquiring minds want to know.

|

|

|

|

|

#55 | ||||

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 24,971

|

Quote:

No one's saying it won't work, and that wasn't the question. The question was about the "proper" way to lubricate the gun, and the way one goes about determining the "proper" way is to consult an established authority--i.e. the manufacturer, a respected expert on the topic, or an established gunsmith with expertise with that type of weapon. Quote:

If the manufacturer of a firearm says the proper way is X and I do Y instead, it may work just fine, and I may have all sorts of reasons, rationalizations and opinions about why it's not a problem (some of which may even actually be valid), but none of them will make Y the proper way to do it because until I know as much about the firearm as the manufacturer does, I'm not the authority on what's proper and what's not. More to the point, if a gun is not running under the conditions that the manufacturer spells out as proper, the owner is generally either entitled to redress from the manufacturer for not providing a working firearm, or, at the least, needs to have his weapon checked over to determine why it is not operating as it should. Quote:

"I not only spray (small pump sprayer, not aerosol) a little Hoppes in the chamber..." "...shot of Breakfree into the chamber..." Quote:

__________________

Do you know about the TEXAS State Rifle Association?

|

||||

|

|

|

|

#56 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,883

|

Bolt wet is one thing. Flooded chamber is another.

But Bill Alexander advised I run a wet bolt in his Grendel. I've run hundreds of rounds through that rifle that way in an afternoon and the bolt/components simply wipe clean upon disassembly. Since then I've run a wet bolt in all my Stoners unless in high dust/sand for extended periods. Then MiliTec. Last edited by mehavey; June 14, 2013 at 11:35 PM. |

|

|

|

|

#57 | |

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 24,971

|

Quote:

__________________

Do you know about the TEXAS State Rifle Association?

|

|

|

|

|

|

#58 | ||

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,875

|

You all have brought up good points on both sides of the argument . My understanding as to why you want a dry chamber was so the case locks up fast and tight and does not slide back and put extra pressure and stress on the bolt and action . You want the least amount of movement of the cartridge in the chamber for many reasons . . Accuracy , and less stress on the bolt to name a few . I do not know this to be true but I would think you would have head spacing issue sooner with a rifle that had a oiled chamber then a rifle that always had a dry chamber . Do to the fact that the brass in the dry chamber is expanding and locking in tight and would not be putting the extra stress on the bolt .

Not sure if it's the same but in my head it seems to be . You get better accuracy from using fire formed brass to your chamber . I believe it's cus it will lock up faster and tighter then a full sized case . Same principle yes ? The least amount of movement in the chamber the better ? I would also add the fact of the possibility to much lube in the chamber could cause problems like to much lube when sizing . only difference is in one of the ways the cartridge is under about 60,000psi of pressure . Sure would suck for your case to pot a stitch then  Quote:

Quote:

Last edited by Metal god; June 15, 2013 at 06:45 AM. |

||

|

|

|

|

#59 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,883

|

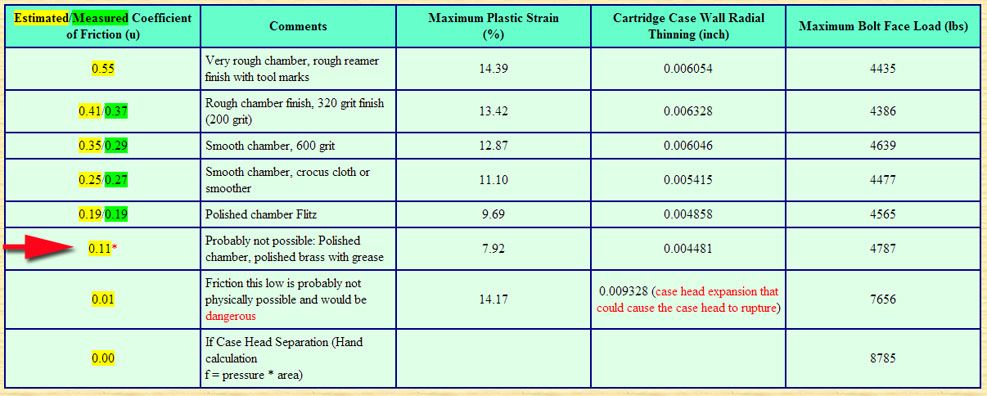

Oil/Lube on Case -- Bolt Thrust Effects:

Folks, please look at the following data/calculations for a a 243 with varying degrees of "smooth/lubed" chamber  Summary Table with Estimated and Measured Coefficients of Friction (About 2/3rds down the page) http://varmintal.com/a243zold.htm Barring grease so thick that it forms a hydraulic lock, slightly lubed cases/chambers just aren't a problem. Last edited by mehavey; June 15, 2013 at 11:04 AM. |

|

|

|

|

#60 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,875

|

The chart is interesting . The marked area that states ( probably not possible - polished chamber , polished brass with grease ) . . Two of the three are very possible and what about a chrome line chamber . Is that not a way to give a surface more lubricity ? Sounds like we are getting closer to it being possible .

You don't think after firing thousands of rounds that extra 3 to 400 FT.lbs per shot will not have an effect on the bolt . I would add the 5.56 round has about 10,000lbs more pressure then the 50k in the test . Last edited by Metal god; June 15, 2013 at 09:52 PM. |

|

|

|

|

#61 |

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 24,971

|

mehavey,

I read the article that the table came from some years ago and it's very interesting. There's only one problem. Some lubricants, including those with molybdenum disulfide--a common component of firearms lubricants--can provide coefficients of friction considerably lower than the 0.11 value that the author assumes is "Probably not possible." Some charts indicate that moly lubes can actually provide coefficients of friction as low as 0.035 under some circumstances. More than 3 times lower than what the author thinks is probably impossible. It's a very good analysis in terms of the mathematical simulations, but the author made an assumption that placed an unrealistically high lower limit on the level of friction attainable. Since his assumption is not consistent with reality, his conclusions must be viewed with some level of skepticism. Using linear interpolation (admittedly not a particularly elegant method) to estimate the bolt thrust provided by a 0.035 coefficient of friction provides an estimate of 6939lbs. That's a 50% increase in bolt thrust over the 600 grit finished chamber. As I said in an earlier post, maybe that's safe and maybe it's not--I don't have a way to say for sure. I can say I won't be trying it myself nor recommending the practice to others. All of which is neither here nor there in terms of the actual question asked by the OP. The answer to that question is that proper lubrication of a modern gas-operated firearm does not include putting lubricant in the chamber.

__________________

Do you know about the TEXAS State Rifle Association?

|

|

|

|

|

#62 | |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

This is from the DPMS web page: DPMS Ammunition warning http://www.dpmsinc.com/Ammunitions-Warning_ep_59-1.html Code:

Ammunitions Warning After extensive testing, we have found that only ammunition manufactured to SAAMI (Sporting Arms and Ammunition Manufacturers Institute) specifications is reliable in DPMS rifles. DPMS recommends the use of high quality, domestically produced ammunition for best results and highest accuracy. For plinking and practice, we recommend only domestic, commercially manufactured ammunition. Please note: the use of hand-loaded ammunition voids the factory warranty. The use of all ammunition listed below also voids the warranty. We have incurred feeding problems with the following: • Israeli ammunition • Korean ammunition • Chilean ammunition • Portuguese ammunition We have reviewed several reports, from several manufacturers', regarding problems using this ammunition. The problem appears to be the bullet contour and the overall length of the cartridge, which is contacting the rifling before firing. This is creating a gas port pressure and chamber pressure higher than recommended, therefore causing feeding and extraction problems due to the increased bolt carrier velocity. In addition, there is accelerated fatigue on internal parts. There are also indications that brass may be out of spec, which could create an unsafe condition. • PMP • South African produced surplus We have used this ammunition in the past for testing purposes and found the brass is extremely soft and can "flow" into microscopic pores and grooves in the chamber creating "sticky" extraction. This has been reported in many types of rifles, but is more prevalent in semi-automatic weapons. • Lacquer Coated Ammunition or Steel-cased, lacquer coated ammunition • Wolf • Norinco • Silver Bear • Any steel-cased (coated or non-coated) ammunition The problem with this ammunition is that the lacquer coating on the case. As the barrel heats up, the lacquer turns to a soft, varnish substance and upon cool down, becomes very solid and difficult to remove. This effectively creates an undersized chamber and creates understandable problems. Your rifle is an investment and it only makes sense to choose quality ammunition for a quality rifle! http://www.olyarms.com/index.php?opt...technical-info Code:

About Ammo - Warning! by Thomas Spithaler Information About Types Of Ammunition This warning comes based on an increased volume of customer calls regarding feeding and ejection malfunctions of AR-15 style rifles. Further investigation of these situations came to prove that the vast majority of these malfunctions were based on ammunition, and not the firearm itself. Following is some of the information that have compiled based on this investigation. Lacquer Coated Ammo If you plan on using lacquer-coated ammo in your Olympic Arms AR-15, please be aware of the following. We have received many recent phone calls, as well as some rifles sent in for repair, complaining about reliability problems in their Olympic Arms AR's. The first question usually asked is, "What ammunition are you using?" The answers to the question, as well as seeing the chambers of the rifles that were sent in are showing us that lacquer coated ammo is clogging the chambers badly. What we are seeing is that once the chamber in the rifles gets hot, it is melting the lacquer off of the casings, and leaving a gelatinous goo in your chamber. Under continuous fire, this is usually not noticed, but once you stop, the barrel cools, the lacquer sets and you now cannot chamber and/or properly extract your ammunition. You will experience this in AR-15's much more frequently than other rifles such as the SKS and AK/MAC variants. In most cases the 7.62x39 rifles have chambers cut to the large end of the safety spectrum so that feeding and reliability is uncompromised by the type of ammunition or the consistency of the case dimensions. AR style rifles, and especially those from Olympic Arms will have tighter chambers so that you can experience a greater level of accuracy that these rifles are capable of performing. Olympic chambers specifically are cut to 5.56 NATO specs via Clymer reamers in all button rifled barrels, and minimum SAAMI spec .223 Remington on all SUM Ultramatch barrels. Our rifles will provide superior accuracy, partly based on that fact. Our recommendations: DO NOT USE LACQUER COATED AMMO. Otherwise, be prepared for the consequences. Additionally, most lacquer-coated ammo utilizes steel cases instead of brass. BAD FOR YOUR CHAMBER. The Consequences: Poor feeding, poor extraction, poor accuracy, and an impossible to clean chamber possibly resulting in a rifle that simply does not work. Although Olympic Arms only warrants their firearms when used with new production brass cased US manufactured ammo, we would be remiss to think that the bulk of our customers do not use remanufactured, imported or reloaded ammo. We know that they will, and do. The reason that our warranty does not cover the use of this ammo is as much to protect you, as it is our product and our product. If you are using factory US new manufactured brass cased ammo, and something goes wrong and the rifle is damaged, the ammo manufacturer will usually take care of any repair costs. If not, and the damage can be proven to be the fault of the ammo, you have some sort of course of action you can take against that manufacturer to recover some or all of the expenses of the repairs. If you use foreign lacquer coated ammo as an example, you have NO options. Is your rifle worth it? Winchester Ammo I'll make this brief. For the reloader, Winchester brass is usually not the first pick. It's not mine. But until recently we have had no problems with Winchester ammunition. As of late however, we have been seeing a great many problems related to oversized brass and blowing primers. Please take this warning seriously. We have nothing against the Winchester company, as a matter of fact we had used Winchester ammo for years as our official testing ammo, but there seems to be a large batch out there that simply does not work well. Recommendation: Stay away from Winchester ammo, unless you are getting the really good match grade stuff, at least for now. What ammo should I use? We recommend that you use brass cased domestically produced new production ammo only. There are many manufactures and types of ammo that meet these specifications, so your options are large. But remember this, any autoloading rifle is only as good as the ammo and magazines you use in it. I will never understand why a person would spend $800- $1,000 on a new firearms, and then go out and buy a whole case of the cheapest garbage ammo he can find, and then complain because his rifle does not work properly when firing it. To me this is a bigger mystery than Bigfoot or the Bermuda Triangle. Use junk ammo, get junk results. Use quality ammo, get quality results. Fine Print Warning! We have all heard this before, but it applies here as well; always read the fine print. There are several well known manufacturers of ammunition that also sell ammo that is manufactured over-seas and then imported to the US. Additionally, most major manufacturers offer "less expensive" lines of ammunition bearing their factory names. I will not single out specific brands other than the Winchester which has caused many a problem, there's no getting around that. The thing that these major brands have going for them is the name recognition. People see names they recognize, and they buy the ammo with confidence thinking it is a good quality ammo. But the fact remains, that this is not always the case. CHECK THE FINE PRINT! I have some ammo in my hand, sold under a major brand name label. I have 6 boxes of ammo, all from the same manufacturer, and they manufactured in 5 different foreign countries and imported back into the US. Italy, R.P. (Haven't figured this one out yet), RSA (Republic of South Africa), R.O. Korea, are all represented on this list. Again, BE CAREFUL, and READ THE FINE PRINT! So what is quality ammo? Here is a short (incomplete) list of quality ammunition in no particular order: Ammunition that has been used by Olympic Arms as test fire ammo Ammo that may cause reliability problems * Hornady Black Hills (new production) Federal PMC (US Manufactured only) Remington (new, non-UMC brand) American Eagle Wolf (lacquer coated types not recommended) PMC (imported ammo only: READ the fine print) Reloaded ammo if not properly re-sized Winchester (imported only: READ the fine print) * Based on customer reported reliability problems What becomes apparent is that the AR15 is very picky about its ammunition. It would be interesting to research the ammunition recommendations of all AR15 manufacturer's and see if cumulatively, that all brands of ammunition are not recommended. I searched for similar warnings for the AK47 and found basically nothing. The difference in complaints is striking. An AK47 will feed and extract basically anything it can chamber. It has zero problems with steel case ammunition. What this shows is that the 7.62 X 39 cartridge is a well analyzed and well developed cartridge. The Soviets obviously looked at different case materials, different tapers, different powders before base lining the cartridge. The AK47 was chosen after a competition of designs and then underwent years of development where top designers picked through the mechanism eliminating failure mechanisms. From what I can tell, the 223 round was a wild cat and the M16 was adopted after a watermelon shoot. Once quantities were issued in combat, the accounts of early M16 malfunctions would fill a book (if they were not classified) and hundreds if not thousands of Grunts died clearing jammed M16’s. While the mechanism was improved, there is only so much that can be done once form and fit are fixed. So it is no wonder that the modern AR15 does not handle steel cased ammunition. The cartridge and weapon were an immature design and today its lack of development is still apparent. From web accounts it even has problems with brass cased ammunition: Problems with sticky extraction of REM UMC ammunition http://www.ar15armory.com/forums/top...buyers-beware/ Steel case ammunition has been particularly troublesome in this mechanism. As an example, at this link, the OP added pictures of as extractor rim torn off a brass case when it was chambered in a rifle which had been fired with steel case ammunition. http://www.theboxotruth.com/docs/edu18.htm The authors of this DTIC were researching a problem I have not encountered: extractor lift. Understanding Extractor Lift in the M16 Family of Weapons www.dtic.mil/ndia/2003smallarms/din.ppt The report begins: Several theories for explaining extractor lift and failure to extract in M16 family weapons have been proposed. If you notice, for maximum extraction reliability the Army had to lubricate the case: For shot #7, the (lubricated ) case coasts along behind the bolt when the ejector is not present, allowing the extractor to lift and then return to the case rim The report conclusion is: Extractor lift occurs during the initial rearward translation of the bolt after bolt rotation stops. Case extraction and ejection successfully occur as long as the case is held against the bolt face by the residual chamber pressure while the extractor lifts and returns to position. To hold the case against the bolt face the authors found they had to eliminate chamber to case friction. Even a dented case had enough friction to create a failure to extract. The AR15 had issues with South African military brass cased ammunition: We have used this ammunition in the past for testing purposes and found the brass is extremely soft and can "flow" into microscopic pores and grooves in the chamber creating "sticky" extraction. The South African Army uses a licensed variant of the Galil, http://en.wikipedia.org/wiki/R4_assault_rifle obviously this mechanism is more tolerant of ammunition differences than the AR15 mechanism. Considering all the posts of the issues shooters have had with steel case ammunition, I think it is not a bad practice to lube your steel case ammunition. While this is a band aid cure, something to rectify an intrinsic design defect by an operational practice, oils will break up the fouling associated with steel case ammunition, will break the friction between case and chamber, and as messy as this practice may be, it will keep the mechanism functioning longer between jams.

__________________

If I'm not shooting, I'm reloading. Last edited by Slamfire; June 16, 2013 at 05:31 PM. |

|

|

|

|

|

#63 |

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 24,971

|

That's a well thought out post.

Your last paragraph worries me a little. We both agree that lubricating the ammunition is a band-aid cure that is employed instead of selecting proper ammunition for the design in question. However, the statement that "...it is not a bad practice to lube your steel case ammunition." is too open-ended in my opinion. Based on the modeling simulation in the link mehavey cites, it appears that it could possibly be a very bad practice depending on the lube used--specifically depending on the coefficient of friction provided by that lubricant. The problem is, I don't have, nor do I know of, an exhaustive source of information on firearm lubricants and their effective coefficients of friction. That means I can't (and I don't know of anyone who can) say which ones are probably safe and which ones might be problematic. That means the only accurate statement I can make (or agree to) under the circumstances is that it might be safe or it might not.

__________________

Do you know about the TEXAS State Rifle Association?

|

|

|

|

|

#64 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

As for the type of lubricant, I am aware the Navy and Army experimented with Teflon coated steel cased ammunition in the 50’s. I think oiled Teflon cases performed best, but the whole thing was more expensive at the time than just using brass cases. I predict the cost of brass will instigate more research into various forms of case lubrication for steel cases. The first use of lubricants on steel cases that I am aware of is the German practice in WW1. They were running out of brass, used steel, and coated 8mm Mauser cases with ceresin wax. Worked so well that only waxed cases were wanted as plain steel cases obviously caused jams.

Modern lubricants are much more advanced than lubricants from 10 years ago. I am aware of lubricants having nano diamonds as additives, there are probably a number of exotic lubricant additives that are inappropriate for use in firearms, and probably cost prohibitive to use as a case lubricant. As Varmint Al’s analysis shows, there has to be some friction between case and chamber or the case will collapse. To date, plain mineral oil, automotive oils, are incapable of causing such a phenomena. However, in blackpowder guns, probably due to low pressure, but, for whatever reason, the chamber must be kept dry and there must be friction between the case and chamber. Blackpowder shooters report wet cases being pulled up into the barrel!. One BPCR competitor told me some of his cases were dragged up to the throat and had rifling marks. I wonder if the crimp did this. As to the historical use of oilers, I went to The Machine Gun History, Evolution, and Development of Manual, Automatic, and Airborne Repeating Weapons by George M. Chinn Lieutenant Colonel, USMC VOLUME I OF FIVE VOLUMES I was surprised to find that case lubricant prevented case head separation in weapons with excessive headspace. This is not a practice I advocate, because I would be concerned with action peening, but evidentially billions of lubricated rounds were fired in mechanisms with excessive headspace. http://ibiblio.org/hyperwar/USN/ref/MG/I/ Do notice that Major General Hatcher is mentioned on the acknowledgements. Schwarzlose Machine Gun, 8 mm. page 231 This system is appropriately designated retarded blow-back. Due to the fact that the cartridge is extracted under relatively high gas pressure, it was found necessary to lubricate the ammunition. Schwarzlose settled this problem by installing, as an integral part of the weapon, a pump to lubricate the cases. This device pumped a squirt of oil in the chamber between each extraction and loading. The combination of the lubricated ammunition, heavy spring, large bolt assembly, and short barrel allowed the use of an unlocked action which proved quite satisfactory. Chapter 16 Revelli Machine Gun --251-- An oil pump for automatic lubrication of each round was an integral part of the receiver. Chapter 8 Nambu Automatic Weapons page 353 All Nambu machine guns were gas operated and air cooled with many radial fins giving more surface for cooling. The earlier models had rectangular gravity oil reservoirs so that as rounds were fed into the feed opening they engaged a spring-loaded lubricator. This action caused oil to flow through perforations onto the cartridge cases. Such lubrication was needed because manufacturing the components to such close tolerances as to permit a workable head space had not been possible at the time. The oil permitted the cartridges to slip back against the bolt until lock clearance was taken up, thereby eliminating the danger of a ruptured cartridge case Chapter 9 Revelli Aircraft Machine Gun page 354 The Italian Air Force during World War I was so desperate for an adequate rifle-caliber machine gun of native origin that it ordered the lightening of the water-cooled 1914 model Revelli. This was accomplished by the removal of the water jacket and use of an air-cooled barrel with longitudinal ribs. It not only gave more cooling surface but also strengthened the barrel, cutting down dispersion. The rate of fire was increased by use of ammunition more thoroughly lubricated by means of a built-in oil pump. Chapter 21 Breda Machine Gun page 416 A large oil reservoir was built into the top of the receiver, directly over the feedway. This lubricator was operated by the recoil and counterrecoil movement of the barrel and barrel extension, squirting oil with each complete cycle on the rounds then being positioned on the floor of the feedway. Page 419 Like all Italian machine guns oil was used freely on the ammunition since head space was not adjustable on the weapon. The fixed relation between the front face of the breech-lock receiver and the gas port in the barrel made impossible rotation of the barrel in order to advance or retract the chamber for correct head space. The oiling of the ammunition was resorted to in this case in order to compensate for the above condition. Chapter 29 Sistar Machine Gun page 465 The light machine gun, while having only a 20-shot magazine, did have a feature that the company made great effort to demonstrate on every occasion. The gunner, without rising, could pivot the swinging magazine forward from the prone position and insert in a matter of seconds a fresh supply of loaded rounds directly from the cardboard container into the feed system. By this ease and speed in loading he could keep up practically uninterrupted fire. The weapon was recoil operated, the barrel having an open jacket that gave it support and a bearing for "floating" the recoiling parts. A built-in oil pump on the left side of the receiver sprayed a small jet of oil on the incoming rounds as each was positioned for chambering. This device was actuated by the recoil and counter-recoil movement of the barrel extension. Polsten Cannon page 521 One of the principal differences between the Polish-designed gun, known officially as the Polsten 20-mm Automatic Cannon Mark I, and the original Oerlikon was the built-up receiver of welded construction which had heretofore added greatly to the machining problem in mass production. The Polsten gun was also lighter in weight, but as the weapon was intended for shipboard and ground use, this did not seem of too much importance to the British. It could be fed both by clip or drum magazine, and could only be fired full automatic. Chinn does not mention that the rounds for the Polsten Cannon were greased but this will be found in Brassey’s “Small Arms” by Allsop and Toomey. In fact, Brasseys Small Arms has a whole section starting page 70 about case lubrication. The Machine Gun Part V Chapter 14 Birkigt Type 404 20-mm (Hispano-Suiza) Cannon --578-- After further comparative tests in late April 1942, it was again definitely decided by the Ordnance Department that all American-made 20-mm automatic guns continue to be made with the chambers longer by one-sixteenth inch than the British regardless of the employment of the same ammunition. This decision was final as far as American production was concerned, but in no way did it change the British representative's view on the longer chamber's performance. Oddly enough, the question was again raised, not by the English or our many proving grounds, but by manufacturers of 20-mm ammunition. In testing their cartridges for reliability of action, they encountered a series of malfunctions known as light-struck primers that were all out of proportion for such a weapon. These were not isolated cases, the reports coming in from practically every maker of 20-mm ammunition that was engaged in function firing his products. Since the munitions companies pointed out that the faint strikes were due to lack of impact on the primer resulting from error in the gun, and not as a result of defective materials or workmanship, it was decided to conduct another test on an extensive scale at Aberdeen. Ninety of the 20-mm guns, M1 and AN-M2, selected from every facility producing them, were expended in this test with all types of ammunition, both from accepted and rejected lots. A complete record was made of every malfunction during the entire test and the probable causes of the trouble. The engineers in charge of the project in the early stages of this test recommended that two modifications should be made to overcome the serious malfunctions: "(1) Shorten the chamber one-sixteenth inch, thus modifying it to approximately the British chamber. "(2) Replace the extractor spring with a solid plug, thus positioning the rounds by means of the extractor. This change would include such modifications to the extractor, the bolt, and the ejector, as were deemed necessary."--588— During war all that can be done is to install and make function as reliably as possible that which is issued. With the mounting of the 20-mm cannon in Navy, planes a series of malfunctions began that could not be properly corrected at the time because manufacture was at the peak of production. The slightest change would practically mean retooling. The most serious problem was the oversize chamber. There still remained considerable variance in dimensions between the chambers of the British and American cannon, even after the latter chamber was made one thirty-second inch shorter Due to an outmoded agreement of long standing, everything above caliber .60 in the Army is considered artillery and the manufacture of the Hispano-Suiza cannon therefore came under this classification. In other words the production of this high-speed machine gun was done under artillery manufacturing tolerances. The resulting poor mating of parts, coupled with the inherent fault of all gas-operated weapons whereby the breech locking key in the receiver is immovable and the position of the gas port in the barrel is permanently fixed, made it impossible to adjust the relationship between barrel and breech lock to establish head space. Thus the most vital measurement in any automatic weapon was governed by chance in this instance. An unfortunate discovery was that chamber errors in the gun could be corrected for the moment by covering the ammunition case with a heavy lubricant. If the chamber was oversize, it served as a fluid fit to make up the deficiency and, if unsafe head space existed that would result in case rupture if ammunition was fired dry, then the lubricant allowed the cartridge case to slip back at the start of pressure build up, to take up the slack between the breech lock and the breech lock key. Had this method of "quick fix" not been possible, the Navy would have long ago recognized the seriousness of the situation. In fact, this inexcusable method of correction was in use so long that it was becoming accepted as a satisfactory solution of a necessary nuisance.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

#65 |

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 24,971

|

Interesting information. I hadn't considered the effect on headspace.

Seems like lubricating the chamber/cases can act as a bandaid for other problems besides excessive fouling or the use of steel cases or other substandard ammunition. I like the ending sentence in your post. I think it sums things up nicely. "In fact, this inexcusable method of correction was in use so long that it was becoming accepted as a satisfactory solution of a necessary nuisance."

__________________

Do you know about the TEXAS State Rifle Association?

|

|

|

|

|

#66 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,883

|

Now the only question is whether regular motor oil -- or high zinc racing oil for classic British engines -- is the best bandaid.

I'm loving it.

|

|

|

|

|

#67 | |

|

Staff

Join Date: February 12, 2001

Location: DFW Area

Posts: 24,971

|

Quote:

A much better question would be to ask what is wrong with the gun or the ammo and then remedy that problem rather than merely applying bandaids and leaving the underlying problem unresolved. The common theme throughout Slamfire's last post was that lubricating the chamber was done to compensate for problems with manufacturing tolerances or other issues that couldn't be readily solved with the technology of the time. It's clear that even then, they were aware that lubricating the cases was not an ideal solution, it was just the best they could do with a bad situation and the limited technology of the time. Fortunately that was more than half a century ago and modern technology can address those issues without having to resort to what one of Slamfire's sources calls "inexcusable methods of correction".

__________________

Do you know about the TEXAS State Rifle Association?

|

|

|

|

|

| Thread Tools | Search this Thread |

|

|