|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#51 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

I am not here scrambling for attention, I have said for years L.E. Wilson made a case gage, my instructions for the L, E, Wilson case gage is dated 1955? '56. the Wilson case gage is a datum based tool, the datum in the Wilson case gage has a radius, it doe not have a sharp edge. Many years ago I drove a case into the gage, the shoulder had the appearance of a Weatherb inverted shoulder. If anyone decides to 'test' my work, do not forget to lube the gage and or case body. I make datums, I drill holes, I have drill bits, I have reamers, drilling a perpendicular hole is not a problem. Problem from the beginning, the datum is not a line with an arrow, the datum is a flat plane. Obsessions with datums, I do not have one, the 308 W datum is .400", I do not insist on using .400", I can use .350" or .375" etc. all I have to keep up with one datum. _Problem, if a reloader is going to make an attempt to match SAAMI specs they are going to have to use the sharp edge. Or learn to use transfers, standards and learn to verify. That can not be a good ideal because there is one of us. F. Guffey |

|

|

|

|

|

#52 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Thanks guys for the good grandpa wishes . I took some pics of the cases lined up and will post after work .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#53 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,896

|

MetalGod,

Did you ever fire/then measure whether the cases resize normally after that? |

|

|

|

|

#54 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

no sorry never had a chance to resize and do new load work up do to the fact they are different cases with a 10+gr difference in weight then the other brass I was using . . I'm also working though another issue with a different firearm and that has been taking up much of my free time . I plan to shoot late this week and have resized 100 or so cases to chamber in the rifle . I just need to load them . I'm pretty sure I'll get to that before I go .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; August 25, 2014 at 01:33 PM. |

|

|

|

|

#55 |

|

Senior Member

Join Date: February 13, 2002

Location: Canada

Posts: 12,453

|

"..."case" head space..." There's no such thing. Headspace is rifle manufacturing tolerance only.

99.99% of all the assorted gauges do one thing and one thing only. They separate you from your money. You don't need any of 'em to load completely safe and match accurate ammo. There is no reason to even attempt to match SAAMI specs. SAAMI specs are tolerances too. Plus chamber specs are ALL + .002" for diameters and .015" for lengths. Plus 4% for pressures. CUP, not PSI. Velocities are +/- 90. Then you get into barrel lengths. SAMMI data applies to a range of velocities in given barrel lengths with approximate changes per inch.

__________________

Spelling and grammar count! |

|

|

|

|

#56 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

SAAMI and the firearms, reloading & ammo's companies acknowledges case headspace is a well known, frequently used common term and is useful in explaining how the case dimension from head to shoulder relates to that of the chamber. Doesn't matter that it's not in SAAMI's glossary.

Wanna get technical? Headspace, like all SAAMI Specs, is not a tolerance. They're a dimension with a tolerance. And SAAMI specs are voluntary; no law mandates their use. Last edited by Bart B.; August 25, 2014 at 04:25 PM. |

|

|

|

|

#57 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Alright now I think we've went a little off topic here . Yes I helped a bit but I never was looking to or really wanted to load to SAMMI specs . My original issue/ problem was why MY measurements changed . Regardless of what they were to start they are off by .003 . Since I started this thread I have sized other brass that I have been sizing to MY 1.622 and they now need to be 1.619 . Something changed for sure what that is I really don't know for sure . Right now I'm thinking a little of two things . The edges of my D-400 insert are indeed rounded compared to the others never used . The other could be my calipers although I'm getting the same measurements using two different pair and styles so it seems more likely my insert has worn .

As for all the other thing that are asked about as possible problems . I'm totally ok with any and all giving me things to look at . Most of you I trust and listen to what you have to say and even attempt to do the things you ask regardless if I think it will work . On more then one on occasion I did not think what I was about to do would work but it did . I'll keep tying because It helps me learn . Sizing my cases smaller now fixes the problem sure but I'm the kind a guy that likes to know why things have changed . And yes I do know it almost always is the nut behind the wheel that's the problem .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; August 25, 2014 at 06:55 PM. |

|

|

|

|

#58 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

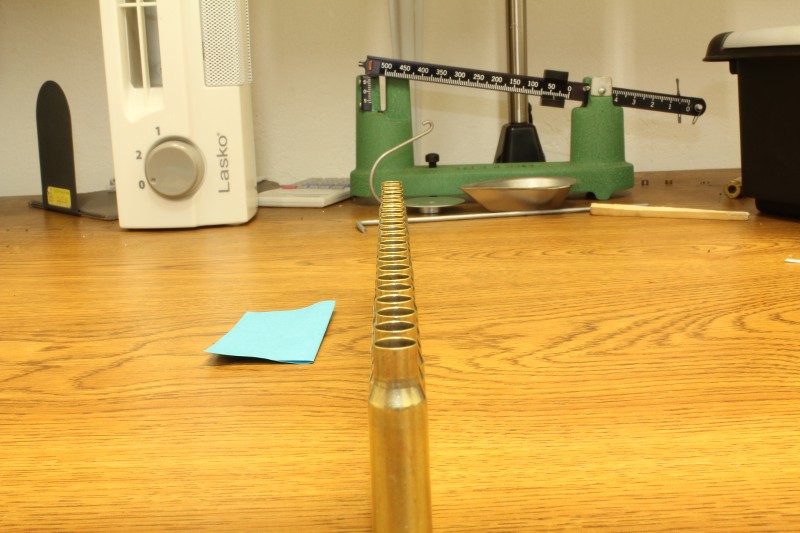

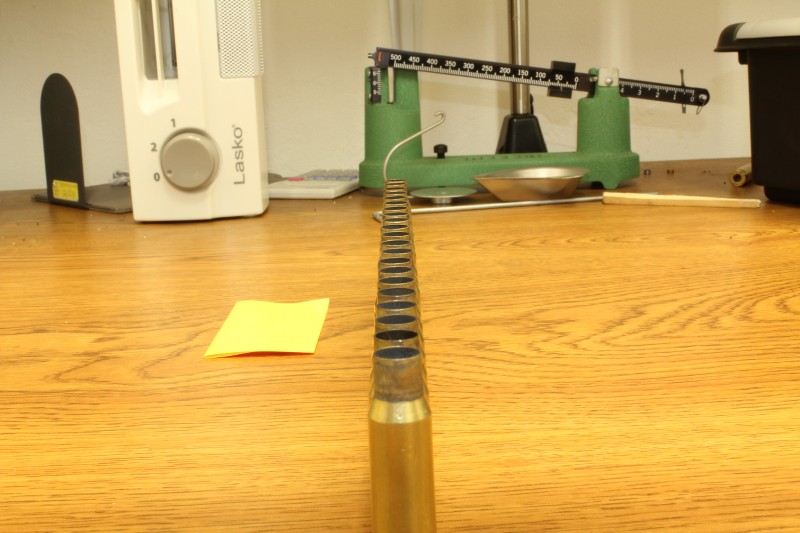

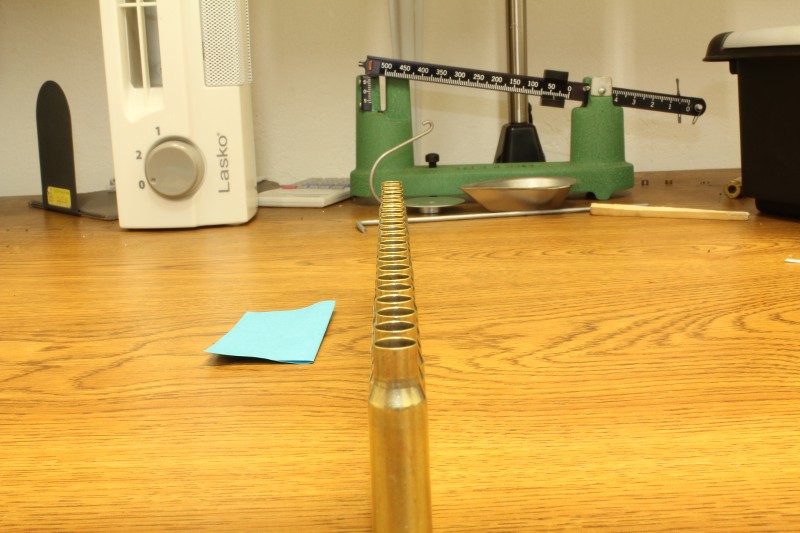

OK here are some cases lined up

LC-10 cleaned once no real prep done  LC-10 cleaned with complete prep including sizing .  These are Remington cases that have been fired from my rifle twice ( uncleaned )  I see some that are not in line with the others in all the pics but the second pic with the cases that have been cleaned and prepped seem the best and the ones shot from my rifle seem the worst

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; August 26, 2014 at 01:16 AM. |

|

|

|

|

#59 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Nice pictures. For every .001" of case head out of square, the mouth will be about .005" tipped out of alignment. .001" out of square = one side of case head is .001" further back than the opposite side. Case length is 5 times as much as the .400" diameter case head flat surface.

Last edited by Bart B.; August 26, 2014 at 08:59 AM. |

|

|

|

|

#60 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Thanks , had to pull out the tripod and dial down the aperture to 29 with a 2.5sec shutter speed

I think the real question here is . How bad are these ? I have no idea what is common for cases and how out of square they normally are in a s factory rifle . Mine look pretty bad in the 3rd pic showing cases fired from my Savage . The thing that gets me here is I thought Savage had designed the bolts to self square or be more true or something like that . I remember talking to guys and them saying something about not needing to do the same things to your bolt as lets say Remington needs because of the design . Maybe it was about lapping the lugs for even pressure or what ever you would lap you lugs for .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; August 27, 2014 at 10:50 AM. |

|

|

|

|

#61 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Shoot groups with both. If you can tell the difference, then you'll know.

My guess is the unsquare ones will shoot 1/3 MOA worse. They're all out of square about the same amount. The more they misalign with the out of square bolt face, the worse they'll shoot. .001" out is good. Some are .003" or more. |

|

|

|

|

#62 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,063

|

MG,

Seems like the out-of-square casehead theory is eliminated as a cause of your chamber jam by how well your once-fired's lined up. We'll have to come up with another explanation. Are you swaging your military primer pockets to remove the crimp? If so, swaging will raise the brass surface immediately around the perimeter of the primer pocket. This flattens back out on the first firing, but it is often two or three thousandths tall (depends on the crimp). If you have such a raised primer pocket perimeter and were able to measure case headspace fit without including the raised area, it could explain the chambering difference. One thing about the Hornady comparator adapter body is that it is offset for using bullet comparator inserts with their Overall Length gauge. For that reason it's not hard to mislocate the position of the case head on the caliper jaw. Getting Hornady's case anvil can help with that, if you don't already have one. Anyway, it may be worth spending some extra time fiddling with your measuring technique. Try pinching the caliper jaws closed over the case between your thumb and index finger rather than sliding the moving jaw with the thumb wheel or pad. This avoids beam deflection. See if it changes your result. I would also do some comparative measurements of diameters. Military brass tends to be harder and more springy than some commercial brass (especially, Federal). Since machine gun chambers are often more generous in diameter than commercial chambers, you may find it is the diameter rather than the length that's the issue. Sometimes, especially if your chamber is snug, you find a small base die has to be used for the first sizing cycle of once-fired brass to get past its spring-back point far enough, and then it behaves well with a regular sizing die afterward. Also see if annealing before the first resizing makes a difference, and be sure the whole shoulder is annealed as well. Mr. Guffey, Yes, that convex radius approach is probably ideal for a case gauge because it is strong and wear resistant and has only one shoulder angle to deal with. A radius just won't allow zeroing for absolute measurements off a comparator insert for the same reason the existing small radius does not. Mostly we just want comparative measurements from a comparator (hence the name) for which all these absolute numbers are moot, but if someone wants to try for absolute measurements after zeroing with the insert bottomed out, then the bottom surface of the insert has to be on the plane where the datum diameter of the hole is. Even a radius shaved back to where its diameter is 0.4000" will have a pretty sharp edge, so the short shoulder I described is all that comes to mind as a solution. That solution still assumes anyone cares or wants to bother. Zeroing on a GO gauge and just adding its length to the +/– numbers still seems to me the most reasonable way to get absolute measurements that match pretty well from one person's copy of the tool to another's. Getting numbers after zeroing on the existing comparator insert is individual. You might get 1.622", while the next guy measuring the same case with his copy of the same size insert might get 1.620" or 1.628" or any other number in about a 0.010" span. But as you have reminded us in the past, all that is less valuable to sizing for a particular gun that getting a take-off measurement from its chamber, then adjusting the sizing die to match, regardless of the absolute measurements either might end up with.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#63 | |||

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

Quote:

Quote:

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; August 26, 2014 at 09:39 PM. |

|||

|

|

|

|

#64 |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

If it don't shoot, fix the rifle. I was going through some stuff this week when I cam across a Winchester Model 70, I had a weak moment, I thought about taking it to the range but got over the urge very quickly. I added oil and cleaned the barrel, magnificent looking rifle. I acquired an old Model 70 stock and thought about installing the rifle in 'old wood', I got over that, I thought I could find an excuse for using my new to me sled, again, I got over that.

That rifle came to me new with the ugliest, longest and largest diameter chamber I have ever seen, Winchester said they were going to polish, hone and or ream the chamber and I ask "Which one of the three 'hone, polish or ream' is going to make the chamber smaller? Winchester had the rifle for what seemed forever when I called them, they said the chamber was too large in length and diameter and was ugly, ugly? I ask them if the chamber increased in length and diameter when they honed it? Or reamed it? or When they polished it? "NO", the rifle was returned to us that way. I wanted a chamber that matched my dies or Winchester dies that matched their chamber. The rifle was returned in a new box with new foam packing. In the beginning Winchester instructed me to shoot the rifle more. F. Guffey |

|

|

|

|

#65 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Guffey:

Quote:

there that is I've been looking for that there that is I've been looking for that  Not much factory ammo through that rifle I suppose  . I have to assume that you have since made the perfect set of dies for the rifle seeing how your a reloader , you make tools , you make gauges ??? . I have to assume that you have since made the perfect set of dies for the rifle seeing how your a reloader , you make tools , you make gauges ??? What caliber ? How does it shoot ? What caliber ? How does it shoot ?

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#66 | |

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

The other rifle was a non Weatherby with a non Weatherby chamber. It has been 20 years, the owner of the non Weatherby called and said accuracy has gone south. I suggested a few fixes, later he called and said the scope mounts were loose, accuracy returned. He does not reload. F. Guffey |

|

|

|

|

|

#67 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

mehavey:

Finally got to the range and fired some of the LC-10 cases This was the LC-10 brass before I fired it in my rifle  This is the LC-10 brass fired once from my rifle .  I had a bunch of sticky bolts . This was on load development when starting at near minimum charge . I was getting a sticky bolt at all charges and have concluded that I sized them a bit long as if I had only neck sized . One in 3 rounds chambered with just a tad of resistance . I took MY comparator  with me and the difference from cases that chambered with no or close to no resistance and the others with some resistance was .001 . Although not completely understood . I now must size my cases .004 shorter then I had been . with me and the difference from cases that chambered with no or close to no resistance and the others with some resistance was .001 . Although not completely understood . I now must size my cases .004 shorter then I had been .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#68 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

I think you rifle's bolt face is way out of square. Enough so that fired cases have to have their shoulders set back several thousandths so the high point on case heads won't align with the high point on the bolt face and cause binding.

If you index a sized case at different clock numbers in the chamber, one whose shoulder's set back only a thousandth or so, and the bolt binds at one point but not with the case indexed 180 degrees out, that's a good indicator your bolt face is out of square. And the reason fired cases have to have their shoulders set back quite a bit so there's clearance from case head to bolt face regardless of how the case is indexed in the chamber. |

|

|

|

|

#69 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,896

|

MG:

The question at this point, is whether the now-fired LC cases will chamber when sized to 'normal' dimensions relative to all your other cases. If they will, then your rifle is fine, and it was the previous rifle whose bolt face was out of square. |

|

|

|

|

#70 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Has my bolt face always been out of square or can they become out of square for one reason or another ? Can it be fixed at the 2k+ round count on a rifle ?

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; September 1, 2014 at 09:08 PM. |

|

|

|

|

#71 |

|

Moderator Emeritus

Join Date: June 25, 2008

Location: Austin, CO

Posts: 19,578

|

How do you square the bolt face on a Savage?

Easy... https://shop.pacifictoolandgauge.com...oducts_id=1291 |

|

|

|

|

#72 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

That Pacific Tool Savage bolt head has an impressive looking appearance. But will its bolt face (where the case heat seats) be square with the barrel's chamber axis? Depending on what the angular difference is between the chamber axis and closed bolt axis on a round, it may well not be.

Lapping the bolt lugs to full contact first helps ensure the bolt will close into battery the same for each shot. The best way I know of to face the bolt square with the chamber axis is to first square the receiver face with the chamber axis. That's done by threading a mandrel into the receiver's barrel tenon threads, then putting the mandrel between centers on a lathe. Run the lathe's cutting tool at right angles to the mandrel axis across the receiver face making light cuts until it's all cleaned up. If it takes .003" of the receiver face, that's how much you want to take off the bolt face to maintain headspace in the chamber. Here's one for Mauser actions; identical to others except for thread dimensions; http://www.midwayusa.com/product/120...-98-large-ring Next, thread a bushing into the receiver with a 3/8 inch or so body diameter end mill with the mill's diameter that of the bolt face specs. A stop on a threaded mill shank lets it be first set to just touch the bolt face and its locking nuts snugged against the bushing, then backed off an amount equal to what was faced off the receiver. But enough has to be taken off to clean up the entire bolt face. That's easy to do with a hand cranked end mill. Here's a set of them for Mausers: http://www.brownells.com/gunsmith-to...-prod7707.aspx Even if the boltrace axis angle in the receiver is a bit off from the receiver axis and/or the barrel tenon thread axis, the bolt face is still square with the chamber axis. That's what's important to keep case head clearance constant, head clearance at a minimum and reduce case stretching unevenly around the non-uniform case walls, all of which contribute to out of square case heads. If the barrel's clocked in for any reason for headspace, it will probably have to be set back one thread then rechambered. If more has to be taken off the bolt face than was removed from the receiver face, take more off the receiver face so it's total equals what was removed from the bolt face. If there's not enough bolt clearance to the barrel breech, then the barrel breech has to be cleaned up to get the needed clearance. All of which means its best to square up the faces before installing a new barrel. Otherwise, there may be a few tiny fit and clearance problems. And talented machinist can do this. Some 'smiths insist on turning the receiver on its axis in a lathe, then rethreading it for the barrel tenon. That typically makes the thread diameter larger and whatever it is has to be transferred to the new barrel's tenon dimensions and the existing barrel will no longer fit correctly. A small angular difference between the reciever/bolt axis to the chamber axis is not an issue whatsoever. There's 'smiths who insist on reaming out the boltrace axis to the receiver axis, then sleeving it to match the bolt body diameter to near zero clearance; not needed at all as everything doesn't have to be in exact alignment. Last edited by Bart B.; August 31, 2014 at 09:39 AM. |

|

|

|

|

#73 |

|

Moderator Emeritus

Join Date: June 25, 2008

Location: Austin, CO

Posts: 19,578

|

Datum to head length and head space issue

Bart, there's no cutting the bolt face to headspace a Savage. You'd just loosen the nut and turn the barrel in.

Since the bolt head pivots anyway, I don't know if has to be perfectly square or at least that's the theory. Also, even if the front of the action is perfect and the bolt face is perfect, the assembler would also need a perfectly square recoil lug and barrel nut. |

|

|

|

|

#74 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Brian, thanks for reminding me of the Savage bolt face and barrel nut fit. I knew that but my write up's just the basic stuff; it has to be adjusted for each receiver type. If the Savage bolt head flattens against all case heads it's chambered, that great, but what about the bolt/receiver lug surfaces being 100% mated when that happens? If they're cockeyed, that introduces another issue. I never thought about this until now. Something I'd like to know more about. Maybe I'll post a query in the The Smithy's threads.

And yes, recoil lugs between barrels and receivers. I've known several 'smiths with mental bandages on their heads from pulling their hair out dealing with that issue on Remington 7XX actions. One reason why David Tubb's Remington extra thick recoil lugs have both front and back surfaces plane/parallel. Blessed are the Winchester 70 actions who don't have all those issues; Mauser 98's, too, for that matter. Last edited by Bart B.; August 31, 2014 at 11:43 AM. |

|

|

|

|

#75 | |||

|

Senior Member

Join Date: July 18, 2008

Posts: 7,249

|

Quote:

Quote:

Loading to SAAMI specifications: I am the proud owner of 4 rifles that are new to me. The owner said one was a 308 W, the rifle looks like a '91 Argentine 7.65mm53. The bore looks new, most of the numbered parts match, complete with a turn down boot, mounted scope and a sport type stock. I could load 5 boxes of ammo (100 rounds) sized and loaded to SAAMI specifications, only to find the chamber is on the long side of the specifications from the shoulder of the chamber to the bolt face, then what? According to the vast majority of reloding forms I should become a fire former, first I size the cases then fire form. And that is the part that does not make sense. reloaders with limited ability and skills have no choice, I am a reloader, I am a case former, I form cases to fit the chamber, I have forming dies, I form 30/06 cases to 7.65mm53, I am not hard heads, I believe full length sizing is a bad habit when the reloader does not know the length of the chamber from the shoulder to the bolt face. Quote:

The rifling in the barrel does not look German, it has a glass finish inside. If it is a 308 W, no problem, I picked up enough parts to build another. One of the other riles is a 336 Marlin 1965 with scope. SAAMI Specs.? I have 200+ 30-30 cases, I will not start full length sizing those cases to agree with SAAMI, the 4 rifles plus parts are my rifles, not SAAMI's rifle. I will size the fired cases to fit my chamber from the shoulder to the bolt face. I received a call from an owner of a rifle that was chambered to 30/30, we discussed options, he called the manufacturer? They said and did the correct thing, they informed him they did not want that rifle in circulation, he returned the rifle, he could receive a new one, they could choose to repair his rifle. I was proud of him, he could check the clearance between the head of the case and bolt face and he could measure the length of the case from the shoulder to the head of the case and and compare the length with the length of the chamber from the shoulder to the bolt face. SAAMI specs? "SAAMI SPECS!!!!", when a new rifle hits the streets new factory over the counter never fired ammo is available. Who knows the length of factory new over the counter unfired ammo? I do, and the Shadow, 'he know'. F. Guffey Last edited by F. Guffey; August 31, 2014 at 12:12 PM. |

|||

|

|

|

|

|