|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: April 29, 2009

Location: Harriman Tn

Posts: 424

|

Sharing headspace measurement techniques?

How about sharing your methods of measuring headspace for those that would like to advance their reloading skills?

|

|

|

|

|

#2 |

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,955

|

Here is one way to set "zero" headspace in a bolt action without a gauge.

Full Length Resize(P-FLR). 1. Put the Shell Holder in the press and raise the ram. 2. Screw the Full Length(FL) Die into the press so it is about a "nickle's thickness" above the Shell Holder. 3. Lube a "Fired" case (walls and inside the neck) and squash it. 4. Remove the Lube and try closing the bolt on it in the chamber. 5. If the bolt closes with no resistance, screw the FL Die into the press about 1/8-1/4 turn and repeat steps 3 & 4. 6. As you feel the resistance begin, slow down how much you screw the FL Die into the press so you are at about 1/16 of a turn, or "Fine Tuning". At some point you will not be able to close the bolt and you are extremely close to having the FL Die in the proper position. NOTE: The reason for this is because the FL Die has begun Resizing the Case-walls down to the Pressure Ring. As it does so, the Case-body lengthens slightly which in turn moves the Case-shoulder slightly forward. Then as the "Fine Tuning" continues the Case-shoulder makes contact with the FL Die and is moved slightly reward(or slightly shortens the Case-head to Case-shoulder dimension). 7. Stop when there is a slight bit of resistance when closing the bolt on the empty case. You now have a "slight crush fit" for the case in that specific chamber, or Zero Headspace. 8. Once you get it where you want it, take some masking tape or a black marker and put a Witness Mark where the FL Die Lock Ring is positioned to hold the FL Die in this position. Loosen the FL Die and return the Lock Ring to align with the Witness Mark and sung up the Set-Screw. Screw the FL Die back into the press and try squashing another case. It should have the same resistance as the previous one. If not, you need to re-adjust the Lock Ring so it does. But you are extremely close to where you want it, so make very small changes at this point. Occasionally check the fit of the cases in the chamber, say every 5th firing just to make sure nothing has slipped. Checking more often won't hurt anything and give you confidence that the Set-Up is still proper. |

|

|

|

|

#3 |

|

Senior Member

Join Date: July 5, 2007

Location: Pacific NW

Posts: 1,310

|

Chamber headspace or cartridge headspace?

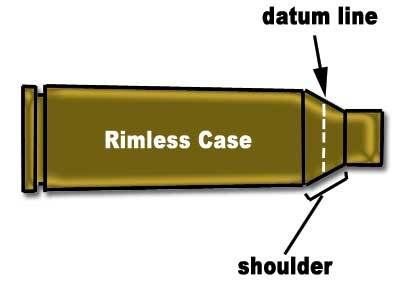

To measure chamber headspace, a set of headspace gauges is usually used to determine if the chamber is within GO/NO GO/FIELD dimensions. I understand that, unless you are finish reaming a chamber in a new barrel (or one that had the barrel turned back a thread), there is little use for a GO gauge. Someone else has already reamed your rifle's chamber to a little over GO before they sold it. The NO GO gauge is the useful one. If you have a rifle that does not close on a NO GO gauge, it has adequate headspace but not excessive headspace. If, after firing thousands of rounds, the stripped bolt closes on the NO GO gauge, you should consider having the rifle rebarreled. The FIELD gauge is sometimes referred to as a FIELD REJECT gauge, because the idea was that armorers in the field would use it as a check to see if a rifle could be returned to service or sent in for a new barrel. Field armorers were not concerned about brass life, just whether the rifle would suffer case head separations with new military brass. Many believe that this gauge still can be used the same way, to operate a barrel beyond NO GO dimensions. Considering the original intent, and that today's shooter may be using reloaded ammo, the least that could be expected is greatly reduced brass life, with the occasional case head separation not surprising. Shims of known thickness can be stuck to the bolt end of a GO gauge with a film of grease to try to determine what actual headspace is for a given rifle. Cartidge headspace, on the other hand, is usually measured with something like a Wilson cartridge headspace gauge. There are shoulders for minimum and maximum permissable headspace. A shooter generally adjusts his resizing die to fall between these two steps, which are usually on the order of 0.006" apart. Semi-auto rifles may require minimum cartridge headspace for reliable chambering, and bolt-actions typically do not. For bolt-actions, a cartridge headspace 0.002" less than the fired case length to datum (in that rifle) is usually OK and results in increased brass life (due to reduced stretching.) There are far more sophisticated tools and techniques available than I have described above. However, I believe the above is generally correct and OK as an introduction to the two types of headspace.

__________________

.30-06 Springfield: 100 yrs + and still going strong |

|

|

|

|

#4 |

|

Member

Join Date: January 6, 2010

Location: Houston

Posts: 70

|

steve4102 and dmazur are both entirely correct. Steve's method is uncomplicated and equipment free and dmazur's is complicated and equipment heavy. I am somewhere in the middle and use a Hornady Headspace Gauge

http://www.midwayusa.com/viewproduct...tnumber=479704 which clamps onto your calipers and measures from the case head to a point on your shoulder which we will call the datum line   So you measure a new case, once fired and neck sized, twice fired and neck sized and so on until your case develops a "crush fit" in the chamber. That will give you the measurement on the shoulder where the case is held in a bind between the bolt-face/case-head and the chamber-shoulder/case-shoulder. Then you can use the gauge to set your die up so that you only push the shoulder back .001" to .002". Then you are working your brass the least and case life will be extended and the chances of a case head separation will be reduced.

__________________

Guns have 2 enemies, rust and politicians |

|

|

|

|

#5 |

|

Senior Member

Join Date: January 27, 2009

Posts: 130

|

Here's how I do it on my Garand.

Measuring fired brass is useless because it's stretched a little long and won't fit back in the chamber. I take the bolt out, pop out the ejector and springs and just set the extractor back in (to help pull the cases back out after testing). I also get my Hornady headspace gage (that will measure the case's shoulder) so that I can actually record a number and check each reloaded round. Depending on the brand of brass I actually need to re-adjust the die slightly each time I load a batch, and I would go nuts if I had to use the rifle each time for that. I full-length size with the die a little loose, drop the case in the chamber, and see if the bolt closes. It won't all the way at first, so advance the die again and try again. I do that until the bolt closes so the right hand lug is all the way down so I can feel a "click" when it bottoms out. I do this with several cases. The ones that just barely close without a click are about .002 longer than the longest ones that close with a click. I figure the actual headspace is between those two numbers. I write the numbers on the cases and keep them in my reloading box and use them to verify the accuracy of my hornady headspace gage and die adjustment when I set up for each batch. It also lets me keep an eye on my rifle headspace and adjust accordingly. I then adjust my die so that the shoulder ends up about 0.003 shorter than the longest case that closes the bolt completely. These end up a shade longer than commercial or GI ammo, but they will allow the bolt to close without resistance 100% of the time. I do all of this simply for longer case life, since I highly doubt that the accuracy difference is enough to notice. If you aren't a big gun cleaner, you might want to try the same experiment with a dirty chamber and see how much space the gunk takes up. |

|

|

|

|

#6 |

|

Senior Member

Join Date: December 1, 2008

Location: Southeast, IN

Posts: 123

|

If you haven't seen it yet, check out this headspace gauge and read the reloading tips. Hope it helps. http://www.larrywillis.com/

|

|

|

|

|

#7 |

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,955

|

Good job JR. That's how I set up my die for my semi-autos as well. Well almost, I do not take the bolt apart.

I will add that I also use the Stoney-Point Headspace Gauge. My original post was to show how to set up the sizing die without one. |

|

|

|

|

#8 |

|

Senior Member

Join Date: April 29, 2009

Location: Harriman Tn

Posts: 424

|

We're getting some really great ideas and techniques here folks. Keep them coming, I'm hoping they will be helpful to others trying to advance their reloading capabilities and even to those that are more advanced.

howlnmad |

|

|

|

|

|