|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

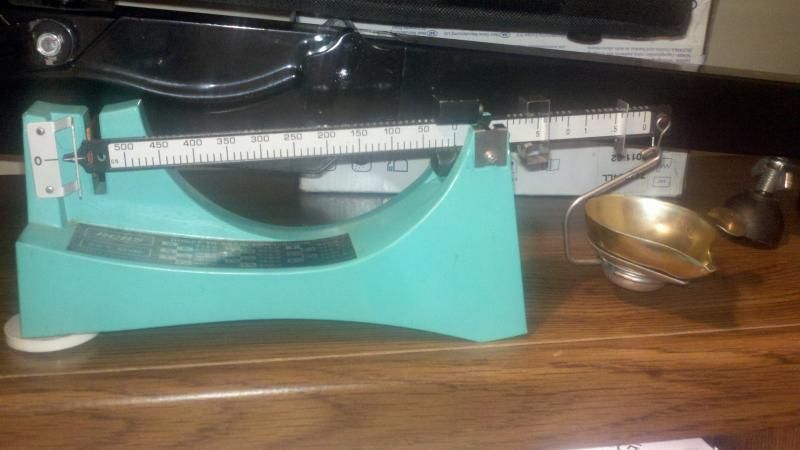

RCBS 505 Scale acting right?

It reads dead on, but I move the .# indicator to purposely throw off the charge to see if the scale would catch it and +/- .1 the scale does NOT move from 0. Even at +/- .2 the scale appears to still be 0. It zeroed just fine, but I am worried about how it is reading.

Desk is verified level with a level. The verification powder is 4.6 grains of W231 verified to be 4.6 by two other scales. I bought this to have a beam scale as a safety scale to verify calibration of my two other scales in the future. It's used off eBay. Zeroed   With the scale set to the charge.   Purposely set scale to 4.4 grains with 4.6 charge to verify it will show wrongly weighed charges

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

|

|

|

|

#2 |

|

Senior Member

Join Date: February 1, 2009

Location: Iowa

Posts: 525

|

I would check the beam knives and bearings. Make sure that they are clean. My old 505 also lets the bearings move within the holders to self-center. Good luck.

__________________

"Of all the things I've lost, I miss my mind the most." A. Brilliant |

|

|

|

|

#3 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

The bearings move freely, but I will take a alcohol wipe to the entire scale.

Thanks

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

|

|

|

|

#4 |

|

Senior Member

Join Date: November 8, 2007

Posts: 2,001

|

Your close-up pictures of the zero reading seem to show a fiber/hair (and its shadow) that may be affecting the beam. Or, maybe it is a crack in the paint that just looks that way in the photos?

I second the notion that it could be dust on the beam knife edges and pivot points. I use a Q-tip to carefully clean those whenever I set up my scale for a use. Of course, you need to be careful that you don't leave a fiber from the Q-tip behind. With clean edges and bearing surfaces, my copy of the exact same scale does allow me to see 0.1 grains difference. But, that is a small difference. You can easily miss it if you don't put your eyeball in the same place as when the scale is zeroed. To solve that problem, I put a fine line on the scale frame behind the beam, as level as I could make it with the zero mark. That way, I can align my eye with the scale by aligning the zero line and the line on the frame, then make sure that the beam pointer is resting exactly between that aligned set of lines. SL1 |

|

|

|

|

#5 |

|

Senior Member

Join Date: December 11, 2009

Location: Northern California

Posts: 1,766

|

I see the hair too and all the other dirt. A good cleaning is needed and then retry your test.

|

|

|

|

|

#6 |

|

Senior Member

Join Date: March 29, 2009

Location: NW Ohio

Posts: 569

|

I use a brush that is used to apply acid flux for plumbing, it has semi stiff bristles and does good at getting any loose dust/debris out of the pivot points. Best part is the thing is like 50 cents at any of the major home improvement places.

|

|

|

|

|

#7 | |

|

Junior member

Join Date: November 12, 2000

Location: Colorado Springs, Colorado

Posts: 9,494

|

Quote:

Different powders through measures will have a tolerance. When I crack open a new LB of powder, I weigh 10 charges and record them on a pc of notepad and tape it to the LB of powders backside. and figure hi/low (ES) and average throw and so forth. Then when I begin reloading I refer to it to see what to expect when loading. The closer you are to a max load the more important this can be. If your ES could take you over max, time to trickle charge. |

|

|

|

|

|

#8 |

|

Senior Member

Join Date: September 20, 2011

Location: Alabama

Posts: 349

|

RCBS 505 Scale acting right?

Would a blast of canned air be appropriate for removing dust from these delicate surfaces, or does that offer negative possibilities of which I haven't considered?

|

|

|

|

|

#9 |

|

Junior member

Join Date: November 12, 2000

Location: Colorado Springs, Colorado

Posts: 9,494

|

Used judiciously it would be. Easy on the scale, not too much slam banging around of it.

|

|

|

|

|

#10 | ||

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

Quote:

Quote:

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

||

|

|

|

|

#11 |

|

Senior Member

Join Date: July 5, 2009

Posts: 869

|

Electrostatic forces: These are generated when nonconductive objects or containers (glass or plastic) are electrically charged, for example, by pouring from one container to another or by air currents. Static electricity can be prevented by maintaining sufficient air humidity (at least 60%), or by using an electrically conductive enclosure that is connected to the weighing pan. Other solutions: Let the sample condition on a metal plate that is connected to the same electrical ground as the balance, ionize the air in and around the balance with an ionizing blower, don't use a plastic draft shield or sample container: plastics are more easily electrically charged than glass.

Electrostatic forces usually show up as a drift in the weighing results (the balances readout seems to stand still after placing the sample on the pan, but than slowly starts to drift in one direction), or in poor reproducibility in repeated weighing procedures. Keeping a clear space around you scale. Static electricity near digital or balance beam scale can affect measurement accuracy just as much as a stray air current. Always use a powder pan made from metal or from static dissipative plastic . You can also wash you scale's pan with a little dish soap and allowing the soap film to dry on the pan. You can also occasionally wipe the pan with a non-scented frabic softener sheet to achieve the same results. Keep items made from plastic away from the scale, including plastic or styrofoam loading blocks, die storage boxes, ammunition storage boxes, Akro bins, etc. Don't forget the static on your body! If you have a carpeted work area or leading to it you can build up a rather large charge. A static spark to electronic powder scale is not only bad for accuracy; it can destroy the scale’s circuits! Even if you don't build enough charge to cause a spark, you can build enough charge to affect your powder scale’s accuracy. You can spray the carpets in your area with the commercial Static Guard TM or make your own with a spray bottle containing a tablespoon or two of fabric softener in a pint of water. Spray either directly on the carpet. Also, touching a grounded metal object once in a while will drain any charge from your body. If you have a Formica covered loading bench you should wipe it down with an anti-static preparation before doing any loading. You should also ground the surface by attaching a thin copper wire to the Formica with a screw and attached the other end of the wire to a grounded surface. |

|

|

|

|

#12 |

|

Senior Member

Join Date: July 18, 2010

Location: Independence Missouri

Posts: 4,585

|

I hate to sound like a perfectionist but when it comes to my scale (exact same one) my setup is most important, Silver00LT, none of those pics reflect a zeroed scale they are all off,,, pick up some new specks and like some mentioned clean beam knives and bushings.

When you trickle powders you will see the scale move with the slightest of weights, just use it correctly.

__________________

Keep your Axe sharp and your powder dry. |

|

|

|

|

#13 |

|

Senior Member

Join Date: April 6, 2013

Location: Alabama

Posts: 286

|

Yeah I am going to thoroughly clean her and retry. I haven't reloaded anything due to this. Being holiday weekend been out and about doing other stuff so have not had a chance to get around to cleaning her up.

__________________

My YouTube MOLON LABE

Training pays off...so keep active with your firearm. It could save your life one day. |

|

|

|

|

|