|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#51 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

I had a pretty good day on Saturday thanks to the help I've had here . The pressure issue were for the most part gone and the rifle was shooting great . I was at the range for 8hrs and it got to 94 degrees out there . Needless to say I was burning out by the end of the day and I think my shooting suffered a bit at the end .

CHRONO When I started out shooting and really all day the Chrono was reading the shots around 150 to 200fps faster then the book said that charge should get . I was chauking that up to the fact of the higher pressures my rifle was generating do to the short throat and bullet seating depth . How ever later in the day I was getting errors all the time and I moved the chrono a bet thinking the reflector things were casting a shadow on the censers . After that it was working again . That just happen to be right before I shoot the loads the were 400fps faster then the book . I also shot some GMM rounds through the chrono at the end of the day and they clocked in 250fps faster then what they were supposed to . I have a Chrony Chronograph . They are the type that fold up on them selves . I now believe the chrono was not fully deployed and that put the sticks closer together by about 1/2 inch or so . The fact I don't really know if that was the case all day or just the last part of the day . I feel I must throw out all the velocity's of the day .  . I will keep the the differences in velocity's from shot to shot cus that should still be correct . YES ? . I will keep the the differences in velocity's from shot to shot cus that should still be correct . YES ? Military brass vs commercial/Federal brass I had duplicate loads worked the only difference was the brass . Brass used was WCC 06 weighing 177gr-ish and Federal weighing the same 177gr-ish . Keeping in mind my chrono issues . Both sets of loads shot the same velocity's . I had 8-4 shot loads of WCC brass and 7-4 shot loads using Federal brass . Powder used was IMR-4895 and the bullet was 175gr smk . The huge difference I saw was the federal brass extreme spread was much less across the board then the wcc brass . WCC had at times 90fps difference and the Federal brass had a 30fps difference . Now those numbers are at the extremes but the WCC brass never got better then 25fps while the Federal brass best spread was 11fps . The other glaring difference was ALL my Federal groups were sub MOA . The spread in MOA with Fed was .540 to .980 MOA and the WCC was ..522 to 1.40 moa with 4 of the 8 groups being 1 moa or more while the Fed brass shot all sub moa groups . I had 1 primer back out using WCC brass with a 36gr charge of 4895 and at MY new max charge of 38.5gr I had 2 heavy bolt lifts at the top . ( when I say MY new max I'm saying that because my starting loads are 2gr less then then the books minimum . If you take 2gr off of the books max my 38.5gr puts me close to the max ) . I did not get the primer backing out with the Fed brass or any heavy bolt lifts . The Federal brass was by far the better brass . I did shoot some loads that I changed the brass from WCC to Fed and reduced the charge as well from the last time out . The powder was Viht N-540 the bullet was 178gr A-max . None had pressure issues and ALL were sub MOA .I did not have any WCC reloads at the reduced charge but did have some over lap of charges . My notes say I had pressure issue when shooting the duplicate over lap charges using WCC brass but not with the Fed brass . I think I'm starting to see a pattern here . The Federal brass had , really no pressure issues and was much more consistent no matter what it was loaded with . There is so much to take in on all this I'm not sure what to ask . So any comments are welcome . On another note working with a Chrono and working up loads . How clean do you guys like your rifle to be ? I had guys at the range say I should be cleaning the bore anywhere from every charge to every 10 to 20 shots . My thought is to test the accuracy and the velocity in the conditions the rifle will be in when used most of the time . I've talked about this before but I'll touch on it again . I plan to clean my rifle every 4 to 6 hundred rounds . Working on the copper equilibrium theory . You are removing as much fouling as you are leaving . you will have a more consistent rifle for a longer round count then if you clean your rifle every 20 rounds . Because of this I have only ran a bore snake through the rifle once in the last 300 rounds . The guys at the range are saying that is giving me false readings because of the fouling in the bore . I say it's giving me a more accurate reading of what my rifle will shoot like under MY normal conditions . What say you ? One guy even said thats were my pressure issue and higher velocity's are coming from but he does not have the whole story . I guess thats good for now .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#52 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

I'd like to add a question about the WCC brass and military brass in general . I'd like to keep using it if it won't take to much work to get it shooting better . I'm thinking I'd be willing to anneal and make the flash hole more uniform if that is one of the problems . Turning the necks down does not sound like something I would want to do . I know I don't want to do all three . I'll just start buying Lapua brass if it becomes to much work .

I'll work on the brass if I can get it shooting like the Fed brass . I pay $68 for 250 rounds of once fired 308 military brass . That seems like a good price if I can get it shooting well . You guys have any short cuts , lol

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#53 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Metal, most max loads of IMR4895 under 175's in a .308 case are about 42 grains. 10% below that (37.8 grains) and most folks get primers backed out of cases 'cause the firing 'in drives the case into the chamber shoulder hard enough to set it back a few to several thousandths. So the primer gets pushed out by pressure building up. I've done this testing 1 grain increments of reduced charges. If there's not enough pressure to push and stretch the back half of the case back until the head stops against the bolt face and reseat the primer, the primer's gonna stay sticking out.

|

|

|

|

|

#54 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Metal God,

I doubt you'll get WCC machine gun brass to shoot as tight as commercial Federal brass. There is a reason Federal brass was chosen for the Mk316Mod0 sniper load over arsenal brass. Annealing will help uniform your neck tension, and uniforming the flash holes might help with getting consistent ignition (and therefore get velocity SD down). That being said, I think you would benefit from a switch to IMR4064 or H4895 over IMR4895 mainly to deal with temp differences which will help minimize muzzle velocity SD. I know this means that you'll have to do the load workup again. I do suspect you can develop an honest Sub MOA load with milsurp brass. I do also suspect that it will be between .5 MOA and 1 MOA once you max out the accuracy potential of components. If that is acceptable to you, then you are good to go. If you are looking for .25 MOA groups, buy Lapua brass. My 168gr match loads shoot around .85 MOA using machine gun LC brass. Using virgin Winchester brass the groups are in the .5 MOA range. Same IMR 4064 and BR-2 primers. Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#55 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

I'm thinking of getting a full length sizing die with neck bushing maybe even the set that has the neck only sizing die with bushing as well . What bushing size ? The website says

Quote:

I get different measurements with different cases . I assume I buy a different bushing size for each brand of cases I'm using ?

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#56 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

The fired case neck has to be sized down to a bit less than the diameter of a loaded round so when it springs back, its mouth will be a thousandth or two smaller than the bullet diameter to get proper neck tension after the bullet's seated. Depending on the thickness of the case neck walls are for a given bullet diameter, different bushing sized are offered.

|

|

|

|

|

#57 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Bart : I know you recommended one of these dies from the get go ,but at the time I did not understand the concept of the bushing die . Here is my hang up now . The reason I want the bushing die is to reduce the neck tension I'm getting now as well as get a more consistent tension .

So if the neck of a loaded cartridge measures .336 and a by the .334 bushing . Is that going to give me less tension then I have now or the same ? It sounds to me I would have the same . If my neck is .336 now do I want to buy the 336 bushing so the spring back will give me .338 and therefore reducing my neck tension ? Can I even go more , like a bushing of .338 to get a .340 loaded neck size ? side note . Placing a order this afternoon on some Remington once fired brass , flash hole uniformer and a bullet comparator set . I'd by Fed brass but can't find any so I thought I'd try the Remington before spending the big bucks on Lapua . I'd like to buy the bushing die as well if I get a good understanding of what I need . going to work now but I'll check the thread later .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#58 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Metal god, yes, use a larger bushing for larger loaded round neck and mouth diameters.

Here's a review of the numbers on these things and how they all work with each other. A loaded round's neck on a .308" diameter bullet may mic .336" diameter. That means the case neck wall thickness is .014" thick. So the outside diameter of the neck on that bullet is .308" plus .014" on one side and opposite that plus .014" on the other side; .336" diameter. Firing that case in most .308 Win. chambers with a neck diameter of .344'. ends up making the case mouth inside the neck about .312" diameter. The outside diameter of that fired round's neck would be about .340" diameter; .308" bullet + .002" clearance all around it + two .014" thick neck walls totaling up to .340" diameter. Size that fired case in a die whose neck diameter is .332" squishes it down to that diameter when the case is full into the die. Backing that case out of the die lets the elasticity of the brass expand the neck. Depending on its metalurgy properties, its outside diameter will expand to some diameter between where it was after firing (.340") and the die's neck diameter (.332"). All this time the case mouth's diameter is .028" smaller than the neck's outside diameter. Let's say it expands to an outside diameter of .335" and has a mouth diameter of .307". That's .001" smaller than the bullet's diameter. Seating a .308" diameter bullet in that .307" diameter case mouth will have a .001" interference fit. That may be tight enough to hold the bullet in place during handling, loading and surviving recoil without setback while in the magazine while another is fired in the chamber. If that's not enough tension for your needs, then you gotta use the next smaller diameter bushing; .331". Conversley, it that's too much holding power on the bullet, neck tension or release force, then by all means use the next larger bushing; .334". If you change the case neck wall thickness, the dimensions in the above scenario will differ by the amount of change. Thicker necks mean tighter grip on the bullet. Uniform neck wall thickness means most uniform neck tension. I've had no problems with a .001" spread in neck wall thickness. Others insist it has to be no more than .0005" Hope this helps you get the gist of sizing cases and the effect their dimensions with the tool dimensions interact. Last edited by Bart B.; September 17, 2013 at 07:38 PM. |

|

|

|

|

#59 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Thanks Bart , that helped a bunch to understand the neck bushing die . I went ahead and ordered one with a couple bushings . I'm going to the range this afternoon to confirm a couple loads that shot well last time out and get there true velocity's . Also loaded some 4064 to see how that will work .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#60 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Back from the range and all went well . Chrono worked good and clocked pretty much everything I shot 80 to 100-fps faster then the book or the factory ammo ways stated to shoot on the box . I shot a 5 shot sting of GMM that had an extreme spread of 4fps

wow no wounder that stuff is so good . The 168gr GMM rounds do get pushed into my rifling when I close the bolt and still shoot amazing through my rifle . wow no wounder that stuff is so good . The 168gr GMM rounds do get pushed into my rifling when I close the bolt and still shoot amazing through my rifle . The IMR-4064 did real good on two loads . I got one .410 group and one .305 group . The .3 moa group had a spread of 18-fps but that was only one round that put me at that spread the rest had a 9-fps spread in the 2440-fps area with 38.5gr of powder behind 178gr A-MAX. I did not have any pressure issues today so I think I'll push the 4064 up another grain , grain and a half in half grain increments hoping to get to the 2550-fps I'd like to get to . I'd like to say I will not load anything or go shooting till the items I ordered last night arrive but that's not likely  I really got the bug now I really got the bug now

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#61 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Well I was going to start a new thread but I guess I'll post this here .

I have all my new toys , Remington brass , FL bushing die , flash hole uniformer . comparator set , OAL gauge . I did not see the fine print saying I need a modified case to use the OAL gauge , so I ordered those in the calibers I'll need . The Remington brass is once fired grade B . It came quite clean and all I did was wipe them down , lube them up and size them . There is a couple things that are interesting about this brass . One is , the mouth of the neck is flared out a bit . Not much but when I size them the die does not size it away . In fact it seems to get worse . No problem I'll just trim the case/neck till it's gone , right ? Wrong the cases are only 2.000" long at best and a good half are a little smaller then that . I only have a fixed length lee case trimmer and it does not trim that short . Here's a pic  The cases fit in my case length gauge and chamber in my rifle no problem so I guess I just fire them and have the pressure of firing them flatten the flared ends ???? As for the FL bushing die . Another interesting thing is happening . It seems to size the brass a little different in the shoulder area . When I use the standard FL die the case after sizing must be on the shorter side when measured in the case gauge or it's a pretty tight fit in my chamber . When I use the FL bushing die the case can be at the max length when measured in the case gauge and still chambers no problem . When comparing the two different cases by eye It appears the difference is in the shoulder area . Here is where it's interesting to me . The FL bushing die seems to set the shoulder back a little more then the standard die . ( not sure If I'm using the right term , the distance from the head to the shoulder seems a little shorter ) and the angles from the body to the shoulder seem sharper . Now I would think if the shoulder is set back a bit the case would measure shorter in the case gauge but it is longer . Not sure if that made sense but here's a pic . do you guys see a difference in these cases .  .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; September 26, 2013 at 11:48 AM. |

|

|

|

|

#62 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

When you full length size a fired bottleneck case, the more you set its shoulder back, the more the neck will grow in length. The brass you sized back has to move someplace, so it goes into the neck area. And that makes the neck, as well as the whole case, longer. The case length gets longer when it's sized.

Do you have a tool to measure the case head to shoulder dimension? If so, use that on cases before you size them to get a starting point reference, then after sizing them to see how much their shoulders are being set back. Fired bottleneck case shoulders rarely need set back more than .003"; .002" for most bolt action rifles. |

|

|

|

|

#63 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

The picture above shows how long the new Rem cases measure inside the case length/head space gauge when sized with the new FL sizing die with neck bushing . That case will chamber in my rifle no problem . Now if I size a case to that length using the standard die I was using before , I can't even get the bolt to close . Why do two cases that seemingly measure the same length in the gauge fit so differently in my chamber ? Both cases OAL are well under the max , measuring 2.0010

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; September 27, 2013 at 01:50 AM. |

|

|

|

|

|

#64 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

Shoot those Rem cases once and see if they don't behave a tad differently after being fire formed. I think what is happening is the shoulder/neck junction is less on your new Rem cases even though the datum line on the shoulder is in the same spot between the two cases. Can't prove or disprove it from where I am, but maybe you might.

Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#65 | |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Quote:

-------- From SAAMI's glossary: CARTRIDGE CASE LENGTH The dimensions from face of the head to the mouth. LENGTH, OVERALL 2. Ammunition: The greatest dimension of a loaded cartridge, i.e., from face of the head to the tip of the bullet for centerfire or rimfire or to the crimp for shotshells or blanks (not to be confused with the uncrimped length in a shotshell. ------- Yes, the case shoulder stops against the case gauge shoulder when it's dropped in. It's not the case length differences nor dimension that's causing one sized case to bind and the other to chamber easily. The one that binds has its shoulder further from the case head than the one that does. Its shoulder's not being set back far enough when it's full length sized. It's the case head to shoulder length that determines whether or not the case binds when the case is chambered as long as the case length's within tolerances. Screw the standard sizing die 1/16th turn further down into the press then lock it there. Size a fired case and see if it chambers easily. |

|

|

|

|

|

#66 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quick funny story . I have my first confirmed sub MOA load . Went to the range today and shot 50 rounds of the same load . Was shooting at 100 , 200 and 300 yards . sub moa was no problem at 100 at 200 , again no problem . when I go to 300 I shot a 3" group , 2.75" group 2.5" group , 2" group and a 1" group .

So what's so funny you ask ? I have/had no plans on using any of the components that are in the load  Bullet is : 190gr smk - I really want to use 175gr smk or 178gr A-MAX . Powder is Viht N-540 - that stuff is spendy and really don't want to buy it at $35 a lb Case is : LC-11 - I only have about 80 of them . I have hundreds of each brand of all the other cases I own . That cracks me up .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

#67 | |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Quote:

If each group was 3 rounds and shot on a different target but using the same sight settings and aiming point on each target, lay them on another sheet of paper aligning the aiming point of each to a reference point. Then pin punch a hole in that paper at each bullet hole for each target. Finally, look at that 15-shot composite group. That's the accuracy you can count on all the time. You can also plot the center of each 3-shot group and see how they are not all at the same place relative to your point of aim. If it was me, I'd forget about that 1 inch group but instead, try to figure out why the 3 inch one happened; isn't that the one you most want to be smaller? But don't spend much time doing that. If you shoot that stuff into no worse than 1 MOA at 300 yards, from a machine rest eliminating all the human variables, they all may well go into about 1/2 MOA. Us humans are wonderful accuracy degrading devices holding onto a rifle and shooting it; none of us hold it exactly the same way for each shot fired. Last edited by Bart B.; September 29, 2013 at 09:52 AM. |

|

|

|

|

|

#68 | |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

Quote:

The issue is the shooter for sure IMO . I have a flinch for sure and I'm working hard to get rid of it . Any pointers to work on that issue will help . I also believe it has a little to do with the rifle set up . I shoot off a bipod and rear bag and seem to do pretty good but I can see my heart beat and other movement quite a bit . How ever I shot another guys Rem 700 that was pretty tricked out . Harris bipod , $1k stock , $1500 scope . The big difference from my rifle to his , well other then the mind blowing amount of money he put in to his. Was he had a non pivot bipod and mine pivots/cants . Anyways when shooting his rifle I could get the reticle to lock in with close to no movement compared to my rifle moving around 1/2 to 3/4 moa . I'm thinking it was his fixed bipod but I cant my rifle when shooting and need the ability level it back up .

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

|

|

|

|

|

|

#69 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

I had a flinch for sure and I worked hard to get rid of it . Any pointers to work on that issue helped me. Here's the best pointer I got....

Have someone else load the rifle such that you cannot see what he puts in the chamber. Then you shoot it with him watching then telling you what happens. He needs to watch your aiming eye most of all. You'll also see what happens. If the chamber had a live round in it, the rifle will shoot and you'll move after it fires. Maybe before it fires, but that's hard for both of you to tell. If you can keep your aiming eye open while the round fires, maybe you can remember where the scope was aiming at when that happened. If the chamber had only air in it, when the firing pin falls, you may jerk your body around. He'll tell you if you kept your aiming eye open. So, you need to learn how to hold still while the firing pin falls and the round fires and don't move until the bullet's left the barrel. And keep your aiming eye open while all this stuff happens. |

|

|

|

|

#70 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

OK new issue because I cleaned my bore to bare metal . It now appears one or two things has happened . either the copper and fouling build up was so great . The fouling it self is what was giving me that short throat or the 830rds I've put down the pipe has eroded the throat quite a bit .

Now that the bore is squeaky clean and I have the OAL gauge and comparators . I can get the exact measurement to my lands and a whole new seating depth I gained .035 of throat with the 175gr SMK and that seems like that would be a reasonable number to gain . How ever gained almost a whole tenth of space with the 178gr A-MAX . My seating die was set at 20 thousandths before I cleaned the bore and that kept the bullet just off the lands . Any longer and I'd start to get the marks on the bullet where it was making contact with the bore . I now can chamber a 178gr A-Max that is seated at 110 thousandths on my seater die and it just barely makes contact with the lands . . Here are the before cleaning the rifle marks on the bullet and the after cleaning the rifle marks on the bullet . The first pic is before .  The next is after I just cleaned the bore to bare metal . I enhanced the scratch so it will show up in pic but that is where the mark is now . I don't no about you but that seems HUGE to me .  I'm not sure If I should be freaking out or not . Is my throat eroding away faster then it should be or was there really that much build up in my bore ? It seems pretty clear I measured something wrong the first time but there is another part to this short throat bullet getting marks on it if not seated deep enough . The marks now go all the way around the bullet . They were only on one side before and really the mark was only on 1/4 of the bullets circumference . If the the issue this whole time was copper , carbon fouling build up in the throat area ,why is there such a big difference with the A-Max then there is with the SMK . why is one 35 thou and the other 90 thou ? Is it as easy as the bullets have different shapes therefore they seat different and were touching different areas when the build up was in the throat ?

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; October 1, 2013 at 12:44 AM. |

|

|

|

|

#71 |

|

Senior Member

Join Date: October 18, 2006

Posts: 7,097

|

830 rounds down the pipe means you have about 89% of useable barrel life left if you assume 8,000 rounds of acceptable accuracy.

Your short throat on the new rifle didn't bother me too much, breaking in the throat (getting rid of burrs from machining) generally takes a few hundred rounds. My guess is that if you had measured at 100, 200, and 300 rounds with a good cleaning in between that is where you would see the most "throat erosion." I wouldn't worry about it right now, but I would measure again in another 500 rounds. Secondly, if the 190 SMK and N-540 did good for you, then look at what that means from your rifle. You have a harmonic "sweet spot" in the 2500 fps range. If you want to replicate that performance with a 175 SMK, you'll need to adjust your powder charge accordingly. Generally the 175 SMK shoots good between 2550 and 2650 fps, but that is just a "rule of thumb" based on what everybody loads for match or sniper ammo (LC, Fed, BH, etc). Jimro

__________________

Machine guns are awesome until you have to carry one. |

|

|

|

|

#72 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Metal God, when the great bore cleaner, Shooter's Choice, first came out in the 1980's, several folks complained their match rifles shot less accurate after cleaning it. So they told their match barrel makers their products were ruined by that agressive cleaner. Boots Obermeyer was almost taken to court by one of his customers demanding a free barrel replacement. But in all instances, the custom barrel makes proved the cleaner got rid of all the fouling build up in the leade and the barrel steel was not harmed at all. Therefore, I think all you did was finally clean your barrel enough to get rid of all the fouling that had been deposited in the leade and hardened there by repeated fouling. Ergo, three cheers for keeping your barrels clean.

When the .308 Win. was popular in high power match rifle competition, the leade would erode away increasing about 1/10th inch over where it was when the barrel was first chambered after about 3000 rounds; that's when accuracy had degraded enough and a new barrel was needed. With the same load using 168's for short range use (200 & 300 yards) loaded from the magazine, accuracy stayed the same for 1500 to 2000 rounds then a very slight loss for the next 1000. The same load with 190's and 200's for use at longer ranges with bullets seated out far enough to be set back a few thousandths when chambered for single round loading, the same accuracy levels as the 168's happened. The load with 168's had a 1/10th inch change in bullet jump distance for the life of the barrel and the 190 load stayed the same but load density dropped a bit as bullets needed to be seated out further to engage the rifling when loaded. One interesting thing happened with the heavy bullets' use at long range with the same recipie. At about 2700 rounds shooting at 600 yards and beyond, an extra minute or two of elevation on the sights were needed for zeros as muzzle velocity had dropped enough to warrant that. And yes, different makes and models of bullets of the same weight probably have different ogive profiles as well as different bearing surface diameters. They'll need different overall cartridge lengths to have the same jump distance to the rifling. If you have access to a 20X or 30X optical comparator, use it to compare your bullets' ogive profiles. You may well be surprised at the difference. Last edited by Bart B.; October 1, 2013 at 07:21 AM. |

|

|

|

|

#73 |

|

Senior Member

Join Date: April 10, 2012

Location: San Diego CA

Posts: 6,876

|

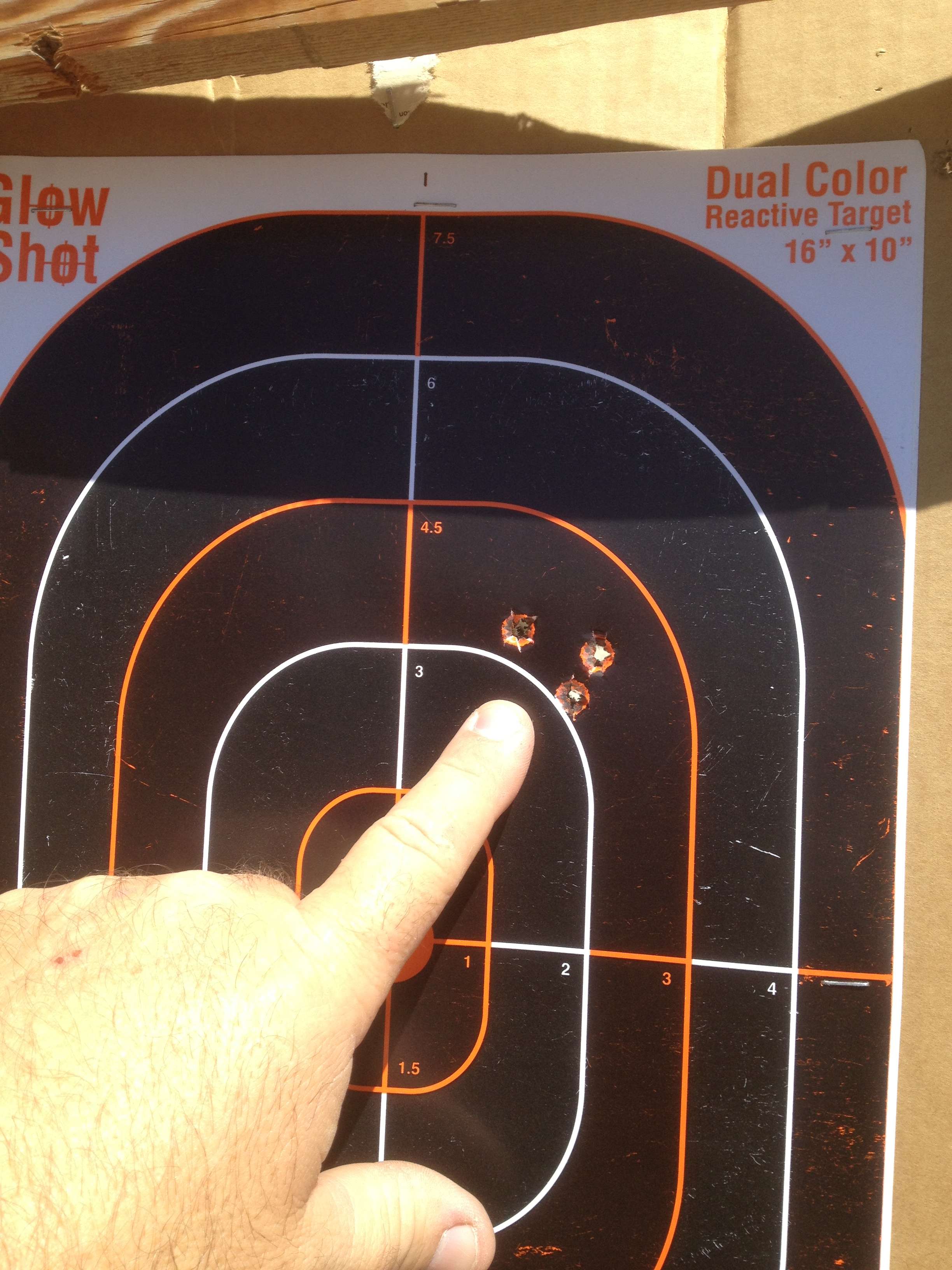

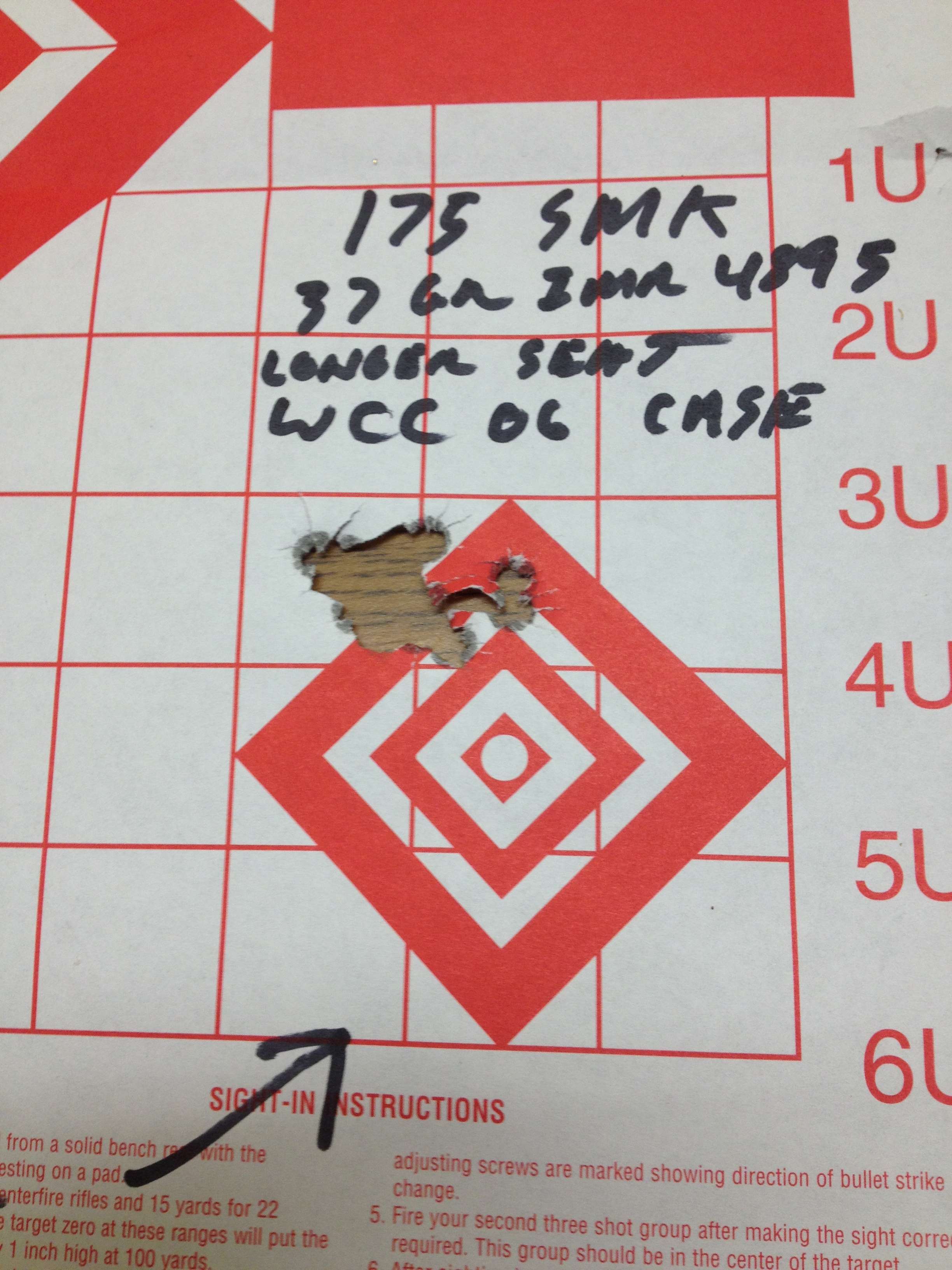

Well I FL sized with neck bushing some of the wcc brass as well as made the flash holes a little more uniform . I was pretty happy with the results . This is a ten shot group fired all in a row in a 2 or 3 min run . the group is 1.15moa my ES was 37.77 and my SD was 12.18 . the velocity is nowhere near what I want but I'll be pretty happy if I can duplicate that load .

EDIT : I started another thread about a pattern I started to see in my groups . http://thefiringline.com/forums/showthread.php?t=533726 Imagen if my stock was tight to the action how good that group could have been  I'm thinking those 2 shots to the right could have been caused by the bedding issue .Who knows how long it's been loose . I'm sure it was not helping my load development I'm thinking those 2 shots to the right could have been caused by the bedding issue .Who knows how long it's been loose . I'm sure it was not helping my load development

__________________

If Jesus had a gun , he'd probably still be alive ! I almost always write my posts regardless of content in a jovial manor and intent . If that's not how you took it , please try again .

Last edited by Metal god; October 3, 2013 at 12:42 AM. |

|

|

|

|

|