|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#1 |

|

Senior Member

Join Date: March 11, 2013

Location: Near Heart of Texas

Posts: 870

|

Accuracy from the barrel or the installation?

We all know that the heart of an accurate rifle starts with a good barrel. Some of the recent post in TFL got me thinking about barrels & accurate rifles. First let me say I'm talking about varmint rifle level of accuracy, not BR or 1000 M. My definition would be 3/4" regularly & even better on a good day. More & more I'm hearing how out of the box Remingtons, Savages, Winchesters, Rugers, etc. bolt guns are doing this with regularity. These all are using mass produced barrels, hammered or buttoned. So is it the quality of the barrel that makes an accurate rifle or the precision on how it is fitted relative to the action & stock? I realize a lot of factors come into play for an accurate rifle, but no one would buy a $400 Krieger & have it cobbled to an action by an amateur smith. It would be installed on a blue-printed or custom action, the bore would have been centered-trued for threading, chambering & crowning & be performed meticulously. So the question becomes, if the level of accuracy I described is wanted, should I have different expectations between a top of the line buttoned barrel versus a standard buttoned barrel assuming each is installed with the same precision & care as would be done with the finest of barrels? For sake of argument, say an off the shelf Shilen blank versus a GM blank which have about a $150 cost separation.

Last edited by BumbleBug; June 9, 2014 at 07:56 PM. Reason: Changed the cost numbers after some research. |

|

|

|

|

#2 |

|

Member

Join Date: November 3, 2005

Posts: 28

|

Threading and fitting a barrel is basic machining really. Getting the bore dialed in to 0 runout before doing any work is important, but again, not something too difficult. My money is on the barrel and I have had awesome luck lately with Bartlien barrels. I think accuracy comes from a quality blank and a good shooter. YMMV

|

|

|

|

|

#3 | |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

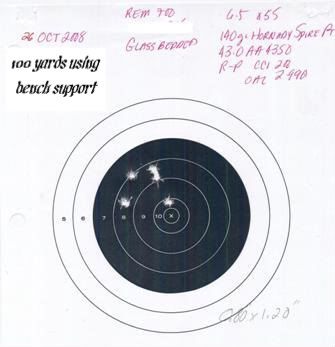

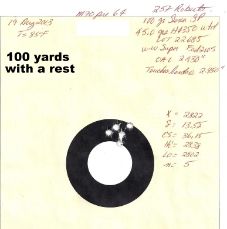

For accuracy, I believe the primary factors are bullets, barrels and bedding. But a bad chambering job, a ham fisted gunsmith, or disgruntled factory worker, can and will ruin what could be potentially a good rifle. The barrel to receiver fit is critical and so is the chambering job. I had a 90’s Remington 700 in 30-06 and nothing I did in terms of load, or stock bedding, really improved the group size. I traded that rifle off, but later I found what may have been the problem. A gunsmith I know was complaining about “Wal Mart” Remingtons. He had encountered a number of late model cheaper Rem 700’s where the barrel and receiver threads were horribly mismatched. The barrels were installed with a type of Locktite to tighten up the barrel to receiver fit. If the barrel and receiver are not a tight mechanical fit, then point of impact is going to vary each shot due to the wobble. That might explain why that Rem 700 was never capable of the finest accuracy even though fed the finest bullets. I have a Classic Rem 700, in 6.5 X 55, that is wonderfully accurate, so production quality must have its ups and downs. Absolutes are never absolutely true, but I am going to state that a bad barrel, one that varies in diameter, the hole through the tube has a lot of twists and turns, a barrel that has been “straightened”, and one that the chamber is an oval, offset from the bore, is never going to shoot well. Of course with infinite time, experimentation, shooters have managed to find one load that actually works well in their bad barrel, but as a general rule, a good barrel will shoot a number of loads well, a bad barrel will shoot most of its loads poorly. Then, comes bedding. A good action in a poorly bedded stock is going to shoot most loads poorly, though, with infinite time and experimentation, shooters often managed to find one load that actually works well in their badly bedded rifle. But as a general rule, a properly bedded rifle will shoot a number of loads well, a badly bedded rifle will shoot most of its loads poorly. I conducted load development for M700 classic in 6.5 Swede and found the thing was not necessarily a tack driver. At 100 yards it did shoot under 2”, which I consider perfectly acceptable for deer hunting. If the rifle shoots 2 MOA, then it will hit within four inches at 200 yards, six inches at 300 yards. That is plenty good, considering that I don’t hold much better with a lightweight rifle off the bench.  The 6.5 Swede action was in a wooden stock. For this rifle, and someone else confirmed their rifle was similar, Remington created a raised area in the barrel channel which created a pressure point. I like free floated barrels. When a barrel heats up it will expand. If there is a pressure point, or a bearing point on the barrel, as the barrel expands, the pressure against the barrel changes. This will cause a change in a point of impact. So with stock channel tools, I scraped the barrel channel, removing the pressure point, and created a clearance so the barrel no longer touched the left side of the barrel channel. I suspect the left side of the barrel touching the stock created a lot of side to side movements. But not all. If the recoil lug is free to slide around in the stock, the action will shift during recoil.  I “pillar” bedded creating columns of Bisonite, and then I routed a humongous amount of wood forward of the magazine recess, and filled that with Bisonite. The final bedding looks awful, with voids, and it is not completely filled out around the recoil lug recess. But I was tired and grumpy and wanted to shoot my rifle, so I put it back together and took it to the range.   Anyway, just bedding this rifle changed its group size considerably. These lightweight rifles are hard to shoot, they are twitchy, they kick hard, and they are very sensitive to stock weld and shooting position. Still, this rifle might shoot under 1 MOA, which is excellent for a deer rifle. Here is a "before glassbedding" target. Everything is at 100 yards. If you notice the wide horizontal dispersion with 140 SMK’s. Sierra match bullets are in a word, superb. In a match barrel they will shoot bug hole groups. This side to side movement indicated to me that something was wrong with the bedding. The action, or the barrel was moving left and right in the stock.  After glassbedding, in my opinion it shot much better. These targets were fired fast, about five shots under a minute, maybe two. I racked the bolt and shot if the crosshairs looked good. The barrel was hot enough to be uncomfortable to touch.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

|

#4 |

|

Member

Join Date: November 3, 2005

Posts: 28

|

Nice write up^

|

|

|

|

|

#5 |

|

Member In Memoriam

Join Date: March 17, 1999

Posts: 24,383

|

A good barrel will be helped with good installation, bedding, etc. But a bad barrel can't be corrected with any tricks, and trying to "fix" is will be a waste of time and money.

But, yes, barrels, both custom and factory, have improved immensely in the last 30 or so years. At one time, a rifle that would shoot minute of angle was a joy and treasure. Folks cut a 1" group out of the target and carried it in their wallets to brag on. Today, just about any factory rifle will shoot MOA and many will do a lot better. The same improvement has come about in ammunition. Today's factory ammo often shoots better than the carefully tailored loads we worked so hard on back in 1950-1970. How much better can things get? I don't know; you can't do better than a 0" group (all shots in a bullet diameter size hole), but I suspect that there will be enough variables in something that such a group will be rare. Jim |

|

|

|

|

#6 |

|

Senior Member

Join Date: October 25, 2001

Location: Alabama

Posts: 18,535

|

Don Zutz, in a rare non-shotgun gunzine article, concluded that the greatest improvement in his later years was the bullets. He had a nice 1930s .257 Roberts that shot better with fresh bullets than any period report ever claimed.

|

|

|

|

|

#7 |

|

Member In Memoriam

Join Date: March 17, 1999

Posts: 24,383

|

Good point, and one I overlooked.

Jim |

|

|

|

|

#8 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

I am of the opinion that bullets have improved significantly over the decades. F. C. Ness provides a number of target pictures in his book “Practical Dope on the Big Bores”. My book is a 1952 second printing. My targets from rifles of the period are better, on the average, than most groups in this book. I am of the opinion the smaller groups are due to today’s better bullets.

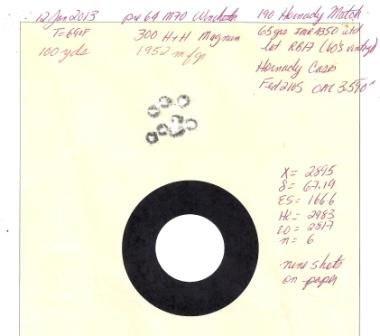

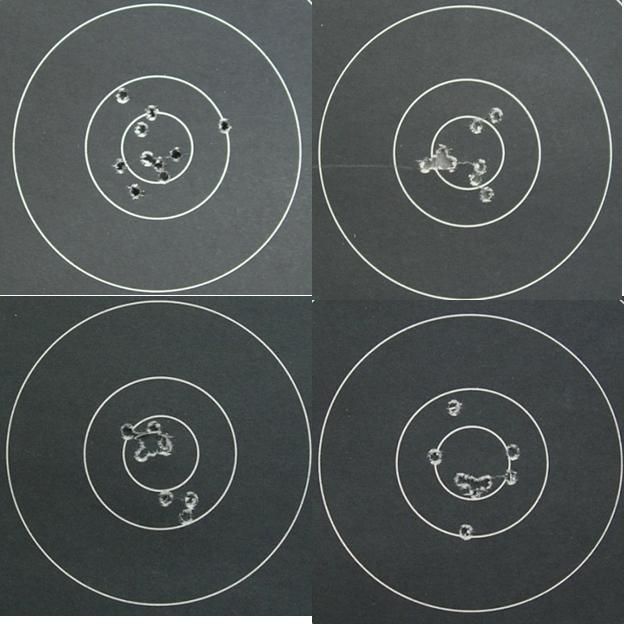

Pre 64 257 Roberts at 100 yards  Pre 64 300 H&H Magnum at 100 yards  This weekend I was competing in a small bore prone match and the shooter next to me was using a modern Anschutz square action, but his barrel was a Eric Johnson barrel he purchased from Larry Moore’s estate. The groups out of that Anschutz were excellent at all distances. I have seen these barrels on rimfires from the 40’s and 50’s. This is an Eric Johnson barrel on a M37 Remington owned by Larry Moore. If you ever see this stamp on a barrel you know it is a premium barrel.  While this M37 “only” has a Remington factory barrel, I shot some excellent groups with its 1941 barrel in competition.   A 400-32X I shot prone with a sling at 100 yards, in a club match  Older small bore shooters claim mystic group sizes with older ammunition, and, it is basically true, that except for senior class, all the National Records for small bore prone were set by the 1970’s. A few later, but the vast majority were set late 60’s and into the 70’s. So maybe small bore ammunition has not improved as much as centerfire ammunition.

__________________

If I'm not shooting, I'm reloading. Last edited by Slamfire; June 10, 2014 at 06:56 AM. |

|

|

|

|

#9 | ||

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Quote:

And in third place is the brains behind the system. Quote:

You've defined quite well where 70% of all fired shots go for those standards. That last 30% will enlarge the group to twice as big or more. Last edited by Bart B.; June 10, 2014 at 06:09 PM. |

||

|

|

|

|

#10 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Slamfire, smallbore ammo's not as accurate today as yesteryear. The best of it easily shot under 1/2 MOA at 100 yards until the early 1980's when the priming mix was changed for safety reasons. It's very rare if any stuff today shoots no worse than 3/4 MOA at 100.

|

|

|

|

|

#11 |

|

Senior Member

Join Date: March 11, 2013

Location: Near Heart of Texas

Posts: 870

|

Question re-phrased

Thanks to everyone for their insightful responses.

Let me try to re-phrase my original question to be more specific. Pick two different barrel makers that make SS barrels by the button process & use air gauging as QC. Both barrels are then fitted to blue-printed Rem 700's & we have excellent ammunition w/match bullets for both. Wouldn't it be reasonable to expect similar accuracy if they were both fitted with the same care & precision? Even if one barrel cost $150 & the other cost $350+? The point being, does the $350+ big name barrel shoot so good because it is just "better" some how or is it that normally a gunsmith would zero center everything & be extra-exact in fitting the expensive barrel? TIA... |

|

|

|

|

#12 | ||

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

Quote:

Quote:

I think they ought to make the ten ring larger to compensate for the poor ammunition! I think they ought to make the ten ring larger to compensate for the poor ammunition!

__________________

If I'm not shooting, I'm reloading. |

||

|

|

|

|

#13 |

|

Senior Member

Join Date: February 15, 2009

Posts: 8,927

|

Either that or shoot at 35 and 70 yards instead of 50 and 100.

|

|

|

|

|

#14 |

|

Senior Member

Join Date: December 29, 2010

Location: Shoshoni Wyoming

Posts: 2,713

|

It's my opinion that the manufacture of barrels and center fire ammo is generally far better today than it was even 40 years ago. However the care of manufacture and quality of 22 rim-fire is less today than it was 40 years ago.

The best barrel and the best ammo will not make a rifle shoot well if it’s put together wrong, but to be honest, barreling and bedding a rifle correctly is not magic. It takes attention to detail, but there are no “hidden secrets.” Any good gunsmith can tell you in detail what to do and what not to do in barreling and bedding a rifle. 1. You need a barrel that is shanked and threaded concentrically with its bore. 2. The front of your receive has to be square to the headspacing shoulder. 3. The chamber should be smooth and set to the tight side of headspace specs. 4. The crown has to be done so the gas-break will be even. 5. The action must be bedded so it’s in a “relaxed” position for and aft. (Not rocking up and down on it’s long axis) and also movement-free in both an axial and side to side directions. 6. Lastly, all barrels have preferences as to what ammo they like, so just because a new barrel doesn’t drive tacks with the first load you try doesn’t mean it’s not a tack-driver. In most cases you do need to spend some time doing load work-ups. |

|

|

|

|

#15 |

|

Member In Memoriam

Join Date: March 17, 1999

Posts: 24,383

|

One thought is that the "name" makers charge more because they do a better QC job and scrap bad barrels; the cheaper makers ship them out.

Jim |

|

|

|

|

|