|

|

|||||||

| Forum Rules | Firearms Safety | Firearms Photos | Links | Library | Lost Password | Email Changes |

| Register | FAQ | Calendar | Today's Posts | Search |

|

|

|

Thread Tools | Search this Thread |

|

|

#76 |

|

Member In Memoriam

Join Date: March 17, 1999

Posts: 24,383

|

I agree, the conclusions in that report seem to match the problem. But I can see how folks, including myself, would think out-of-battery firing. The symptoms are similar since the bolt really was out of battery with high pressure in the chamber. What I didn't realize was that the bolt was driven out of battery by high port pressure while pressure was still high in the chamber.

How much the fact that the upper is a piston type played is not clear, but I suspect that even a full length gas tube gun would have had the same problem with pressures that high. It is probably that at least some of those bent cartridges were from standard length tube guns. Something to think about and hopefully recognize early, before another disaster. Jim |

|

|

|

|

#77 |

|

Senior Member

Join Date: October 21, 1998

Location: Colorado, USA

Posts: 4,308

|

Actually Jim, the "symptoms" are not the same. The shearing of the lug on the extractor, along with the vaporization of the brass are clear indicators of gross over-pressure while in battery, which I pointed out early on in the thread.

OOB will often bend the extractor, but in most cases we can find a witness mark where the extractor was forced against a piece of the extension. OOB also does not result in the vaporization of the brass and the resultant coating of the bolt. |

|

|

|

|

#78 |

|

Senior Member

Join Date: November 19, 2002

Location: Mississippi

Posts: 963

|

Mark, I first thought the head cut-loose. after a closer look I said out of battery. Would not this indicate the round was not all the way home?

|

|

|

|

|

#79 |

|

Senior Member

Join Date: October 21, 1998

Location: Colorado, USA

Posts: 4,308

|

No. In a bolt gun, yes, but not in an AR-15. If you have a poor quality chamber, or it is dirty, we can often see the scratch marks on the brass. Otherwise, I need to look at it under a microscope, and in many cases clean the soot off the case to see the drag marks on that kind of case when the pressure allowed premature opening of the action.

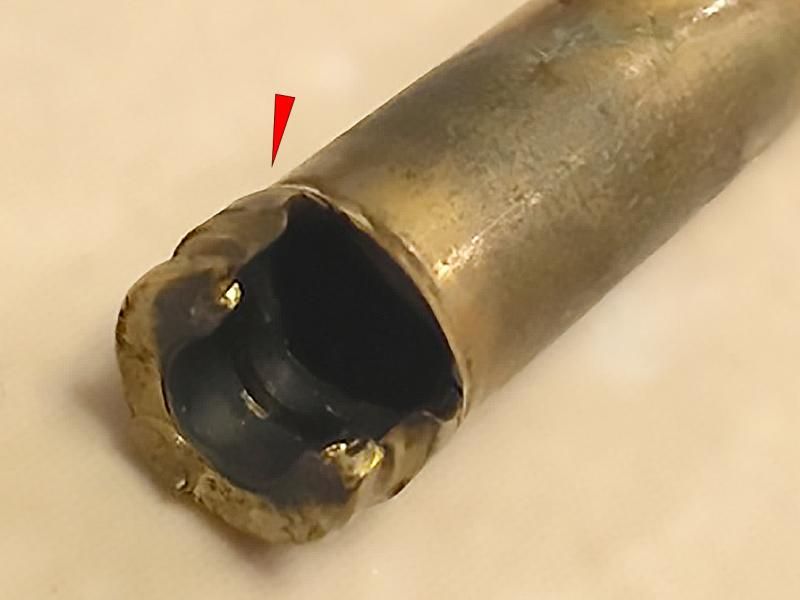

When you combine the operation of the AR-15 with the nice horseshoe at the extractor location, that is almost certainly an ammo issue. However, when I work on a case professionally, I also put the case into the SEM and identify the first location of fracture. All that picture indicates is that the round was not fully chambered when the case wall became over-pressured. But it does not tell you if the round was chambered prior to fracture without the other indicators. AR-15 barrels are almost impossible to blow up. I have over-pressured them to a (measured) 300Kpsi over-pressure. The failures from over-pressure in an AR-15 are unique to the platform and include gas block (or tube) fractures, bolt fractures, carrier fractures and case head ruptures which most often occur when the pressure is too high when the action starts to cycle. With the 5.56 rounds in a normally set-up rifle, that occurs when the pressures exceed about 80Kpsi. What is interesting to note is that in larger bore AR-15s, like the .450 BM for example, the "over-pressure" starts at a much lower level and the "wall" is considered to be about 44Kpsi for the .450BM. One of the indicators I use when I do a professional forensic examination of a failure in an AR-15 is the measurement the gas tube adjacent to the exit from the gas block. If it is bulged, that is another indicator of gross over-pressure as well as excludes the OOB failure mode. It is really looking at all of the indicators for all of the failure modes. Some exclude others while some are present in more than one mode. |

|

|

|

|

#80 |

|

Senior Member

Join Date: November 19, 2002

Location: Mississippi

Posts: 963

|

Gotcha, Another clue would be the ejector flow.. That would indicate it was locked at some point too. wouldn't it.

Thanks. |

|

|

|

|

#81 |

|

Senior Member

Join Date: October 21, 1998

Location: Colorado, USA

Posts: 4,308

|

Yes.

|

|

|

|

|

#82 |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,896

|

Listening to you two guys, reading the cited report above, and re-looking at both brass and bolt

with rim chunk still stuck in the claw... I'm even more inclined to diagnose case failure while being ripped out of the chamber under excessive pressure. ...and that a punier extractor claw (like found today on a lot of new commercial stuff designs) would have just ripped through the rim and left the case (and action) intact. |

|

|

|

|

#83 |

|

Junior Member

Join Date: July 24, 2010

Posts: 4

|

Just to see if I'm tracking with this so humor me!

Because it appears that the primer pocket has been totally blasted out-would this indicate the case head was NOT against the bolt face when the "explosion" took place? I would think that the way the bolt head "encapsulates" the case head, it would have a tendency to trap or slow down the high pressure gas jet that completely blew out the primer pocket area. No? |

|

|

|

|

#84 |

|

Senior Member

Join Date: October 28, 2009

Posts: 614

|

I have a couple of thoughts on this situation.

A friend had a case failure in his CZ 527 .223 bolt gun. The burning powder became like a cutting torch and it actually cut off part of the bolt face. It actually melted part of the brass. Here is a picture of his failure:    Also, if the brass was resized incorrectly, if the shoulder of the bass was pushed back too far it would cause too much space between the bolt face and the head of the case, or the way it is said commonly is that there would be too much head space. Obviously the case failed, the question I am thinking is whether the bolt was closed or not. My guess is that the bolt was closed, that the case failed, venting the gasses backwards, thus blowing the mag out, etc., and the super heated brass at the head was soft and when the rifle cycled it ripped the brass apart. Just a guess. Here are the photos for this particular failure, I don't want to confuse people with the other photos I added.

__________________

SirGilligan - "If you find your back is up against a wall, maybe you have been backing up for too long." iOS Apps: BallisticsGL Gun Log Gun Log SPC WatchForce Last edited by sirgilligan; October 12, 2014 at 11:39 AM. |

|

|

|

|

#85 |

|

Junior Member

Join Date: July 24, 2010

Posts: 4

|

I again go back to the question of whether or not the bolt was closed. I think that the bolt was NOT closed and the evidence is the melted brass that is visible covering the entire bolt head.

If the bolt was closed I would assume the molten brass would NOT cover the bolt head on the outside as the bolt head encompasses the head of the cartridge. This should keep the brass from covering the entire outside surface of the bolt head and should keep the majority of it inside the bolt face. |

|

|

|

|

#86 |

|

Senior Member

Join Date: October 21, 1998

Location: Colorado, USA

Posts: 4,308

|

The evidence is that the bolt WAS closed at firing, but opened when the pressure was still significant. I again will say, you have to be able to look at all of the evidence on concert with the operational parameters of the weapon system.

|

|

|

|

|

#87 |

|

Junior Member

Join Date: July 24, 2010

Posts: 4

|

You are obviously the expert and my questions are just from a theoretical perspective.

What is the evidence that you see that causes you to make the call that the bolt was closed? Is it because of the evidence of brass that's shown below the cut that contains the extractor? Are you assuming that the molten brass flowed down the seams of the extractor and left it's evidence on the outside of the bolt? Just curious!!!! |

|

|

|

|

#88 |

|

Member In Memoriam

Join Date: March 17, 1999

Posts: 24,383

|

Mehavey wrote:

"...and that a punier extractor claw (like found today on a lot of new commercial stuff designs) would have just ripped through the rim and left the case (and action) intact." No, because the bolt is not being pushed back by some outside force; it is being driven back hard by the case itself and the high pressure gas trying to escape. The case head has about vaporized from that very hot, high pressure gas. There is no case rim left and very little of the solid case head. If the analysis is correct, and I think it is, it would have made little difference what kind of extractor was involved or what shape of bolt face. That bolt opened too soon because of excess pressure, leaving the case unsupported while still under immense pressure. I think the short barrel, with a short distance from the chamber to the gas port, played a role, but standard rifles had problems with carrier bounce driving the bolt carrier forward before the next round in the magazine could rise enough to be fed. I also wonder about the role of the piston vs the gas tube. The latter might be a bit more forgiving. But the fact is that with that kind of pressure, there was going to be trouble of some kind, sooner or later. Jim |

|

|

|

|

#89 | |

|

Senior Member

Join Date: June 17, 2010

Location: Virginia

Posts: 6,896

|

Quote:

backward and any effort to extract begun. While that might eventually prove to be the case, the fact that it blew at the extractor location on the case might also support that being where greatest stress was experienced before it finally let go. |

|

|

|

|

|

|