|

|

|

#1 |

|

Senior Member

Join Date: November 30, 2014

Posts: 298

|

Quickload help?

Hi guys, I was wondering if anyone could help me. that had quickload or something like it.

If I use Hornady FMJ BT 55 grain bullets, loaded at NATO spec, that would be OAL 2.200, max 26.3 @~62,000 PSI. My question is if I give the round another 50k of space and load them at 2.250 using the same bullet, what would the max load be getting the same ~62,000 PSI? Thank you in advance. |

|

|

|

|

#2 |

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,968

|

Typically the longer the OAL the higher the pressure.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: November 30, 2014

Posts: 298

|

Longer OAL is less pressure, is that what you meant?

If there is more space between powder and bullet, the result is less pressure. So if I increased OAL, I can add more powder and get the same PSI as shorter OAL and less powder. http://www.bergerbullets.com/effects...e-cbto-part-1/ |

|

|

|

|

#4 | |

|

Senior Member

Join Date: December 24, 2008

Location: Loveland, CO

Posts: 1,476

|

Quote:

__________________

NRA Benefactor Life member |

|

|

|

|

|

#5 |

|

Senior Member

Join Date: December 23, 2005

Location: Minnesota

Posts: 2,968

|

Nope , I meant the longer the OAL the Higher the pressure.

|

|

|

|

|

#6 | ||

|

Senior Member

Join Date: October 21, 2010

Posts: 1,028

|

Quote:

Quote:

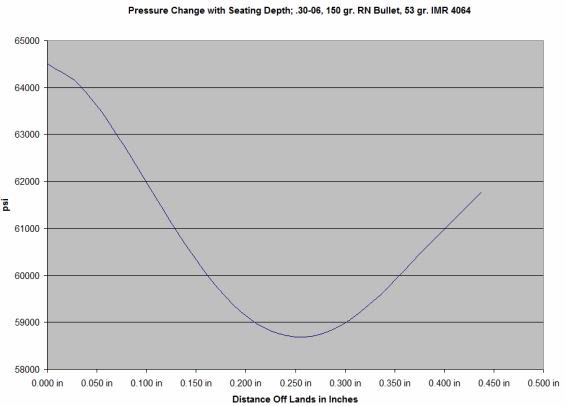

I stole this graph from one of Steve's old posts. It's for .30-06, but it illustrates the principle. At 2.250" OAL, how far off the lands is the bullet in your rifle?

|

||

|

|

|

|

#7 |

|

Staff

Join Date: March 4, 2005

Location: Ohio

Posts: 21,743

|

CAUTION: The following post includes loading data beyond or not covered by currently published maximums for this cartridge. USE AT YOUR OWN RISK. Neither the writer, The Firing Line, nor the staff of TFL assume any liability for any damage or injury resulting from use of this information.

I actually produced that graph originally, after I got hold of a copy of the Brownell study. I have since updated it with a little more complete information:  The original study data shows the pressures all about 20% higher, but the numbers rely on the Lame theorem for correlating strain with pressure, and the Lame theorem is for an infinite cylinder, which a chamber is not. Hence the adjustment. Brownell's theory for why that pressure minimus exists is that when a case neck opens to release a bullet, gas starts leaking out and bypassing the bullet. This stalls the pressure rise, and in very detailed measurements you can make out the small hesitation in the pressure rise as a small step in the 10,000-12,000 psi range. That stall limits how high the peak pressure will eventually get. As the bullet gets closer to the throat, the gas has less time to bypass it so the stall goes away. The pressure minimum in the curve is where gas bypass has ceased to be the dominant term in determining pressure and the size of the powder space under the bullet takes over being the dominant term. Here's another image of an actual measurement, reproduced with kind permission from Jim Ristow, though I added the ovals and their arrows and their text and the text regarding permission as required by the board policy on reproducing copyrighted material and its derivative work (my additions make the final image derivative). The higher pressure curves are with the bullet touching the lands, while the 20% lower pressure curves are from seating the bullet 0.030" deeper to get it away from the lands, allowing more gas to bypass. If he seated the same bullet deeply enough, pressure would start to rise again. The pointed bullet nose of the TNT bullet opens the throat to bypass with less depth change than the more gradually tapered ogive sides of the round nose bullet used for the data in the first illustration do, so the difference shows up in less seating depth change.  9MMand223only, You have maybe a few problems here. First, you never said what the powder was that you used. The change in pressure with change in charge weight varies with the non-linear characteristic curves of each particular powder, so QuickLOAD could not be used without that information even if it did account for throats. Without exact bullet nose shapes information, though, it has no way to do that. All it can do is tell you what the pressure will be if the freebore is so far beyond the seating position of the bullet ogive that you are still below the minimum pressure point that pressure v. seating depth curve. In some chambers that works out to be so, but in most I wouldn't count on it. Even though you didn't name a powder, I am going to guess it is either an Accurate or a Ramshot powder. That is because you said you were loading to NATO spec. Accurate and Ramshot are distributed by Western Powders, and Western publishes the only load data I've ever seen with two different sets of peak chamber pressures for .223 Remington and 5.56 NATO. It's a technical error. I've called them and pointed out the exact same lot of reference ammunition tested in the U.S. using our conformal type piezo transducers and in Europe, using their channel type piezo transducers will measure 55,000 psi here and 62,366 psi there. The loads are identical. Indeed, the U.S., having developed the round, supplied NATO with the reference ammunition that produced that reading. The idea is our 5.56 NATO ammunition produced under the SCATP 5.56 protocol, and their 5.56 NATO ammunition produced under the EVPAT protocol, should perform identically in all weapons so it is interchangeable in all weapons. The two different protocols use the two different transducer types. The problem is that Western didn't get a European channel piezo transducer for their 5.56 NATO load development. They did it all on a conformal pressure transducer, a fact I verified over the phone with their technician. As a result they've produced loads that will measure about 70,000 psi measured under the EVPAT protocol. In short, it's too hot to qualify as NATO spec. And there's yet one more problem with this: all true NATO compatible ammo has to meet not only a peak pressure number, but a gas port pressure number ± around 15% and velocity numbers within NATO limits so they have the same ballistics so NATO rounds from different countries don't require different sight settings on any particular weapon that fires them. Western didn't measure that, either. As a result, those loads are likely to be hard on gas systems. They will also exhibit increased rate of throat erosion. Since the pressure is still below proof pressures, they won't blow guns up, but they will put some extra fast wear on them. And that's not to mention they will wear out brass sooner. I explained all the above to a Western technician over the phone. He said "oh! I'll pass that along". He clearly didn't know about any of this. I hope they'll correct their load data soon. Because the above effect is more measurable than predictable, in your shoes I would use a chronograph while I worked up a load from the starting load level at the greater seating length (and I would be using the .223 data from Western and not those high pressure 5.56 loads). Then change the seating depth to look for velocity changes to see if pressure is going up or down. It is possible to deduce a matching peak pressure load from that information and the gun's expansion ratio. I should get time to help you with that in a couple of weeks, though probably not before. You'll need time to collect velocity data for different seating depths anyway. Try to fire at least fifteen rounds at each seating depth to get a good size sample to average the velocities of.

__________________

Gunsite Orange Hat Family Member CMP Certified GSM Master Instructor NRA Certified Rifle Instructor NRA Benefactor Member and Golden Eagle |

|

|

|

|

#8 |

|

Senior Member

Join Date: November 30, 2014

Posts: 298

|

Thank you, I should have been clear. I just would like to know what quickload says the pressure would be using any rifle powder of your chosing. Any powder. Pick AA2230, or varget, anything is fine. Using max book load at 2.200, what does quickload say, using the same bullet, any bullet of your choosing, and same max powder charge, is the PSI if you make it 2.250, and assume that its nowhere near the lands. Does quickload say its 5k less pressure, 10k less? I was wondering. Assuming its nowhere near the lands. I do not know if quickload can be told how close to the lands? If so lets say 2.250 is 30k off the lands, and 2.200 is 80k off the lands. My testing backs up this theory, because on my chrono, I decrease OAL in powders/bullet combo's, FPS goes up. Not down.

In my huge amount of tests using a chrono, more OAL is less FPS, less OAL is more FPS, but I should have been clear that its an AR, and that the lands are not near the bullet, so pressure from being too close to the lands, is not a factor. I am sorry about that guys. That would be a major factor in a bolt gun. Or a pistol. |

|

|

|

|

|