|

|

|

#1 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,078

|

Bullet coating part II

After going through the powder coating process and giving copper plating a try, after USPS lost the first shipment, I finally received a new batch of the Bayou bullet coating from Donnie, that he FedExed to me.

What you get is a two part mix and you add acetone, tumble and bake. I just ran a small batch of 150, 230 grain 45's for the first run. I mixed 5ml of the color, 5 ml of acetone and 1 ml of the catalyst. Adding about 1 tea spoon to the tumbling bullets and baking at 365 for 10 min. Let them cool and re tumbled them with another tea spoon of the mix and baking for another 10 min. The tumbler I built is a paint bucket I found at home depot that is sort of D shaped, figured this would work for agitation, and uses disposable liners that are cheap so I don't have to worry about clean up. I smashed the one at the center of the photo to see how well it stuck to the bullet and there were no signs of separation. Next test is to load them up and see about smoke and leading.

|

|

|

|

|

#2 |

|

Member

Join Date: February 17, 2012

Location: Las Vegas

Posts: 64

|

You're testing powder coating too, right? It will be interesting to hear you compare & contrast the two coating methods.

|

|

|

|

|

#3 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,078

|

Here is the powder coat thread.

http://thefiringline.com/forums/show...bullet+coating The Bayou method is to chunk a few hundred into the tumbler, add the coating and let them spin around for 30 seconds. The powder coat method is to stand them up one by one, dust them with the powder and bake. The 150 above were baked twice so actually took longer but there was a lot less handling. Not to mention it was 150 vs 24 being coated. The bottom of the powder coated bullets are also not covered. |

|

|

|

|

#4 |

|

Member

Join Date: February 17, 2012

Location: Las Vegas

Posts: 64

|

I thought I saw it somewhere, but can't find it now - what's the cost of the Bayou stuff & how many does it coat? I'll be looking for your range report too.

I'm powder coating also. Without coating the bases, I can do about 80 in a batch that fits in my small toaster oven. There is more handling involved in that; between the two methods I think it's going to come down to cost for me (I'm OK with additional handling to save $$). |

|

|

|

|

#5 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,078

|

$100 of the coating will do 20,000 bullets (+ acetone and electricity). The 150 I did above used up. $0.75 worth of the coating.

|

|

|

|

|

#6 |

|

Member

Join Date: February 17, 2012

Location: Las Vegas

Posts: 64

|

Well... I may have to look into this then. That's very reasonable.

I'm still on my first container of Harbor Freight powder coating... I'm guessing that jar will do 2000 or so? |

|

|

|

|

#7 |

|

Senior Member

Join Date: May 27, 2007

Posts: 5,261

|

This is very interesting. If it also cuts down on the amount of lead blown out into the air, that would be a very good thing. Our highest exposure to lead is when we fire cast bullets. Lead particles are blown into the air. Given that OSHA Limits for exposure in the workplace are: .

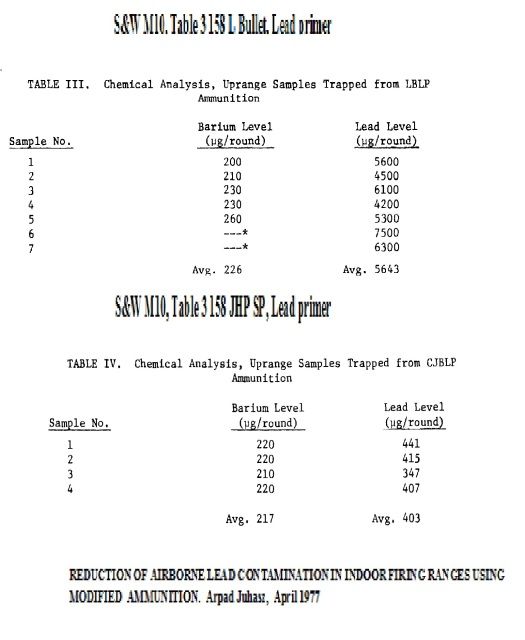

OHSA Regulations (Standards – 29 CFR) / Substance data sheet for occupational exposure to lead, #1910.1025 App Permissible exposure: the Permissible Exposure Limit (PEL) set by the standard is 50 micrograms of lead per cubic meter of air (50 μg/m3), averaged over an 8-hour workday. You can see that the amount of lead in the air from each shot a cast lead bullet with a lead primer is 5643 μgs, the lead primer with a copper jacketed bullet gave 403 μgs. If this coating technology reduces the lead in the air by the same amount that is a very good thing indeed.

__________________

If I'm not shooting, I'm reloading. |

|

|

|

|

#8 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,078

|

After reading Slamfires post I ran a little experiment. An uncoated bullet next to a coated one on an aluminum plate with a torch below.

The uncoated bullet went so fast that it finished melting even after I removed the heat from the bottom, you can still see the rings left from sizing. The coating is the thin inside the grease ring and a little lead leaked out from there. It is still intact on the bottom though. |

|

|

|

|

#9 |

|

Senior Member

Join Date: November 22, 2006

Posts: 3,078

|

I finally got around to shooting and recovering one of them. I had already sized all of the bullets I had on hand and Donnie suggests sizing them after coating and I didn't take the time to run them through the sizer again.

At first I was a little disappointed to see where the coating was removed by the rifling. So I decided to load up some Precision Bullets, that I have shot tens of thousands of and have been happy with for a decade. I was surprised to see that the bullets I had coated held up better than the Precision coating. I am going to load up a few hundred and shoot them in the match this weekend and take before and after photos of the barrel. |

|

|

|

|

|