P.O Ackley’s handbooks are interesting from a historical perspective but contain dangerous , unscientific results and conclusions. I bought them because I was interested in the strength of old military actions and heard he blew a number of them up.

Unfortunately he used his 270 Magnum cartridge, Hi Vel #2 , did not use a pressure gage, so his results don’t really translate into something where you can say “a M98 can withstand this much pressure”. You can somewhat compare the results between actions, but since the real limit on “action strength” is the cartridge case, and the “stronger” actions support the cartridge case better, his tests are very limited beyond the entertainment value.

His load data was published in an era where chronographs were few so there is a lot of data on how much powder it takes to get a velocity. Since this is not pressure tested in anyway, copying some of that data will surely result in blown primers if not blown rifles.

The section on his Ackley Improved cartridges, and his “proof” that straight taper cartridges reduce bolt thrust is totally useless and potentially dangerous.

Cases don’t act as wedges or inclines. Unfortunately they stretch. They don’t carry load, or should not carry load, when they are expected to carry load, as in the Lee Enfield, they inevitably fail at some condition; cases are simply a gas seal.

At the time ole PO was selling his Ackley improved (AI) cartridges, he was blowing out the shoulders, straightening the case, to increase powder capacity and raising pressures. It is obvious that ole PO was taking flak from folks who were claiming that his high pressure cartridges were overstressing the action.

Savants on other forums give out a rule of thumb that a 40% increase in case volume provides a 10% velocity increase, implicit is the assumption that this is isobaric. This may be a crude rule of thumb, and I have done nothing to verify this.

Below are comparisons of Ackley's published data compared to pressure tested data.

49th edition of Lyman Handbook, the max load of a standard 30-30 with a 150 grain bullet and using 28 grs IMR 3031, the velocity is 2145 with a pressure of 38,000 cup.

In Ackley’s own handbook, the maximum load for a 30-30 AI for a 150 grain bullet using IMR 3031 is 38 grains for a velocity of 2700 fps.

From web data, the case capacity of the 30-30 Ackley vs the unImproved Winchester parent differ by 5%

http://www.gmdr.com/lever/3030atext.htm yet here you have Ackley stuffing in 10 additional grains of powder and claiming a velocity increase of 125% over the standard 30-30.

The only way to get those sort of velocities through incredibly high pressures.

If you go to your 1957 Gun Digest, factory ballistics for the Winchester 180 grain Super Speed 30-06 is 2700 fps. Modern reloading data shows you can push a 180 Barnes with 55.7 grs IMR 4350 to 2685 fps, in close agreement with older factory data.

Ackley’s handbook gives reloading data of 61 grains IMR 4350 with a 180 grain bullet for a velocity of 3053 fps.

Noslers shows a max load for the 30-06AI of 56.5 grs IMR 4350 with a 180 gr bullet at 2835.

For the 30-06AI Ackley is putting 5.3 additional grains of powder in the case and claiming a velocity increase of 113% over the parent cartridge. His data is pushing bullets 218 fps faster than modern pressure tested ammunition of the same case.

The only way to do this is through incredibly high pressures.

Clearly anyone now, or then, who had access to a ballistic lab or even crude rules of thumb would be able to say that the only way Ackley was able to achieve those high velocities was through extremely high pressures.

Ackley was getting high velocities from his improved cartridges, cartridges which were being used in actions not designed for those levels of pressures. P.O. wanted to show that his high pressure cartridges did not increase bolt thrust so he ran a rigged experiment to protect his reputation and prove a bogus point, that is straight walled cases reduce bolt thrust and therefore his overpressure cases are safe to use in standard actions.

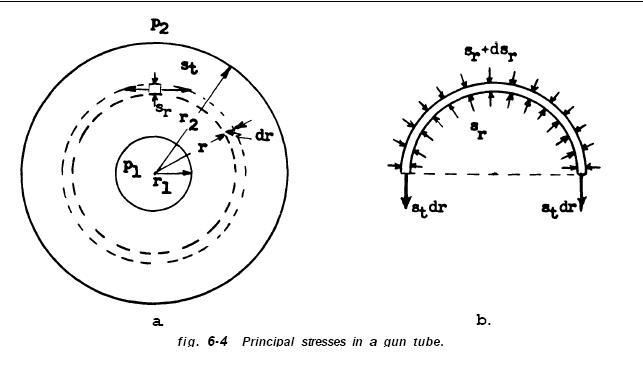

With perfectly clean chambers and clean cases there is parasitic friction between the case and chamber and that will lower bolt thrust disguising evidence of pressure. This does not mean you can just add more powder to the case as radial stresses on the barrel have not changed. Ackley totally ignores radial stresses on barrels. Barrels have their pressure, fatique limits and they don’t go away because of case taper.

When a barrel spilts in half at the chamber, the results are not pretty:

http://thegunzone.com/m1akb.html

When you read his M1894 Ackley Improved test, Ackley starts off by claiming that no one knows the design limits of actions, which is a lie. What is certain he did not know, but that does not mean someone does not know. Designers are not going to provide that information to the general public, and it shows the limits of a skilled machinist when it comes to matters of mechanical engineering design. Ackley does not know, does not know how to calculate such things, does not know that increasing pressures above design limits reduces the fatique life of parts, therefore he goes off in the direction if the action holds it for a couple of shots, the pressures must be safe.

P.O Ackley cartridges are very interesting and P.O’s test of a straight sided cartridge holding pressure without a breech block has been duplicated. The tester swabbed the chamber out with alcohol swabs between shots. The Ackley cartridge held. However the other cartridges, such as the 30-30, 35 Remington, blew out of the breech at 1900 fps. A 150 grain cartridge case flying at 1900 fps will go through both sides of most people's skulls.

Read carefully Boatright’s papers one of which he shows how a 308 case, in a clean chamber, can lock in and hold pressures by itself up to 25K psia.

Go to Jim Boatright’s web page.

http://www.thewellguidedbullet.com/

Look for yielding of the brass case in these studies

http://www.thewellguidedbullet.com/m...al_studies.htm

However once pressures go above 25K psia, Boatwright shows the brass case stretches and if not supported, the case head will blow off.

Regardless of taper, cases are made out of brass and will stretch. There may be bolt load reduction due to friction and stretching but it is inconsistent and not to be relied on in any way.

If you notice, P.O. Ackley never printed experiments conducted with a 30-06 or a similar high pressure cartridge. I am certain if he had reported the results, it would have been a litany of case heads blowing out the back of his lug less rifles at lethal velocities. It is likely he did, given all the actions and barrels he had around, I believe it is more credible that he ran tests in a number of Ackley Improved cartridges but only published the test that supported his theory. We see this all the time when reputations and money are at stake. If he did not, then he should have bought a lottery ticket because he was very lucky. We do know that Ackley and others did not conduct sensitivity tests, varying chamber finish, (chrome for example), powders, primers, or much of anything else. There are axial loads which must be taken into account and case taper does nothing to reduce them, in fact his straight taper reamers reduce barrel thickness when used in a standard barrel. I totally disagree with the conclusion that Ackley and others have drawn, that his cartridges reduce bolt thrust and therefore a user can just pour the coal into the cartridge and let fly.

Due to the unscientific and dangerous nature of the articles in his handbook, the dangerous and overpressure loading data, it is my opinion that the best place for his handbooks is in the delete folder.