February 2, 2014, 10:18 PM

February 2, 2014, 10:18 PM

|

#5

|

|

Senior Member

Join Date: November 18, 2005

Location: On the Santa Fe Trail

Posts: 8,249

|

This was a lengthy tutorial so I have to break this down in a few posts.

Quote:

The fix for the mag box is simple. Ten minutes with a Dremel and the protrusions are ground down a little. I measure the mag box before I start grinding with a caliper. I try to take off about .050".

I don't want to remove too much, just enough. I reassemble the rifle -- minus the follower and spring -- and torque accordingly. Open the bolt, stick a couple fingers in the action and make sure it has a little wiggle room. If the box is still binding, it won't budge. It should move a little side to side at this point.

If all is good, I polish the metal a little where I've been grinding and hit it with a blue pen.

As I stated before, I believe the action flexes upon recoil. Kimber's slave bedding aides that issue. The recoil lug is small and the lug inlet in the stock is spacious.

In my opinion, the lug needs to be bedded tight to eliminate this issue. Some guys bed the entire action, some drop a dab in the lug recess and some guys give everything a nice skim bedding.

I usually bed the action forward of the mag well, the lug and a portion of the shank. I also left the shank area free of bedding and allowed the barrel to float all the way to the lug. This has worked well too.

I prep the stock with a Dremel and alcohol, then tape it off.

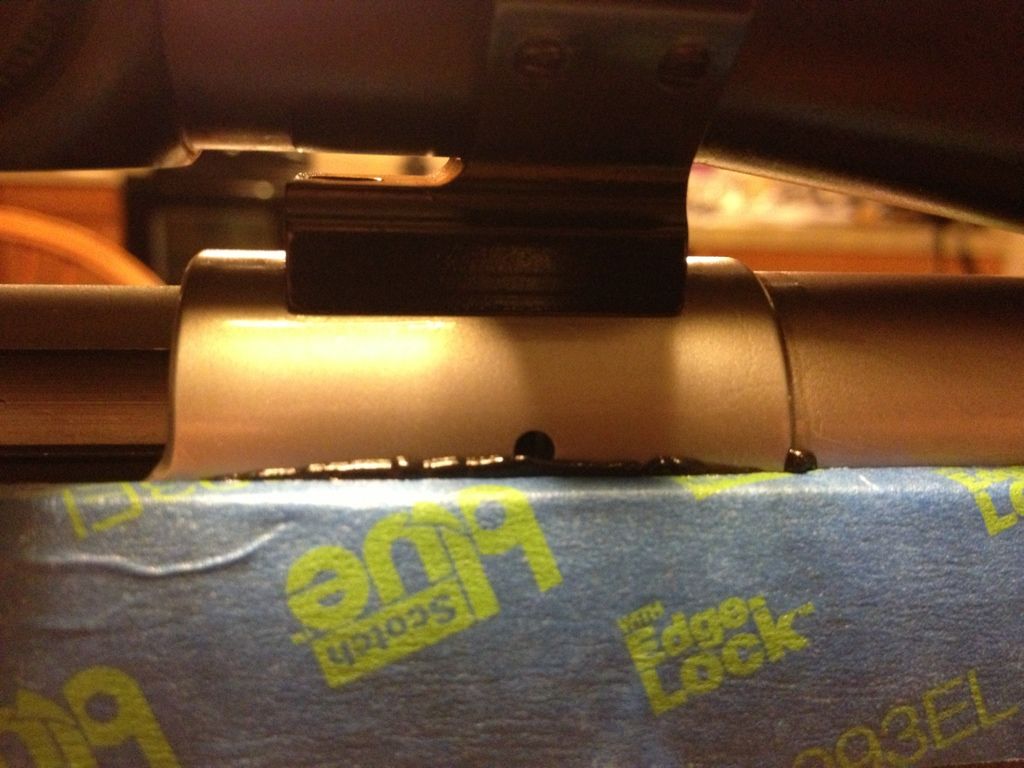

The pics below show the method I use when I float the barrel all the way back to the lug. Doing this, I only apply bedding to the sides and back of the lug recess. You'll still get some ooze on the front of the lug

After bedding compound is in the stock...

I don't tape the bottom or front of the lug. I know some do, but I want it tight on a Kimber. After the bedding cures, I usually Dremel out the bedding in the bottom of the lug well so it doesn't bottom out.

I use a bedding stud from Brownells (same as 700) to make sure I have things centered nicely in the front pillar. I tape the stud to allow for minimal clearance and then start spraying. I use Hornady One Shot as my release agent and I've never had a problem. I spray everything (with the stud in), let it dry, then spray again.

Once the action is in the stock, I insert the action screw in the tang. I tighten the screw two-finger tight. I do nothing to the front stud. My goal is totally stress free bedding.

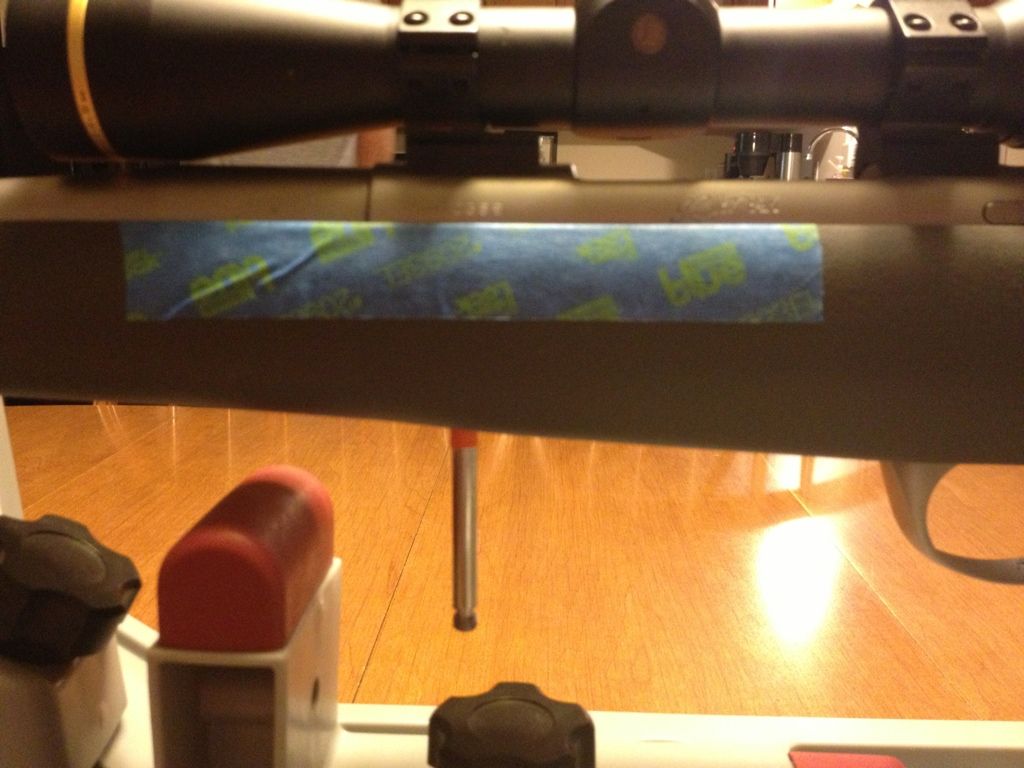

Forgot to mention -- I put a couple of wraps of tape on the barrel near the end of the forearm. I do this to keep the barrel centered in the channel. You can also adjust the spacing of the barrel in the channel when inserting the tang screw. I do both to make sure things are straight..

|

__________________

NRA Life Member

|

|

|