Me & BCall got on a trade & I had dressed all my 38-162 Lachmillers & he wanted fresh off the press !!

This mold is a work of art & I decided not to have it vented as it mite be a millionares dream 1 day so I cast BCalls & ya just can`t get in a hurry when the mold gets to temp , it blows out the drive bands is the best way to explain it !

I tilt it ,I pour slow-fast & still ya gotta let it cool a bit !!

Now I have no problem waitin but the problem is I can`t get a handle counting or tappin my foot or other wise gettin a consistent time for coolin & most of the time let it cool too much & get wrinkly boolits !!

I`ve run temp up & down & the only way to get a well filled boolit is to let the mold cool then pour a couple of cycles at 780-810f with the vave adjustment wide open & pressure cast em !!!

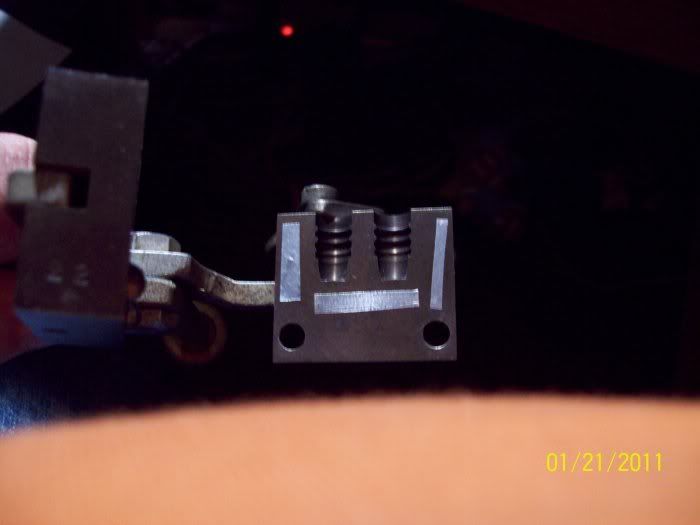

So I came up with some auto electric induction shielding tape , it`s .002 thick & has a stiky side.

When I put the strips on I can see just a tad of lite thru the mold halves , is this gonna work ??

I`ll cast some tomorrow fosho !!! but just a few to see how they run thru the sizer !!