Quote:

|

I would like to see a comparison of processing (sizing and lubing), the same number of bullets using a Lyman 450.

|

dahermit, when I size AND lube I use my 450. Sizing and lubing in two separate operations would be a pain, like trading in my Dillion XL650 for a single stage press. I find pan lubing quicker if I don't have to worry about resizing, but that's just me.

I don't place "each" bullet in the pans, at least not separately. They are placed in the pan 100 at a time, which explains how perfectly spaced they are. I glue two of those 9mm white plastic Winchester? 50 ammo trays together as a tool for putting them in the pan. I made 10 of them so far. It takes me a few minutes to load the bullets into each, but it makes it easy to do while watching TV or whatever. It's like filling primer tubes

This is the only chance I have to actually pick up the bullet by hand and inspect it if I feel like it. After that, it's placed by the 100 lot all at once in the pans. It takes 2 squirts of lube wax per pan. It takes about 15 minutes to harden where I can remove it in one piece as shown in the photo. I then reload more bullets, more lube, and while those cool I'm melting more lube and extracting the bullets. The bullets are not cut out. They are simply pushed out. I use a chop stick (don't ask), and can push the bullets out faster than I can count.

Like everything else, it becomes a system. Both my wife and I shoot IPSC pretty seriously, so between the two of us we go through a lot of rounds. If you know a faster way of doing this, I'm all ears!

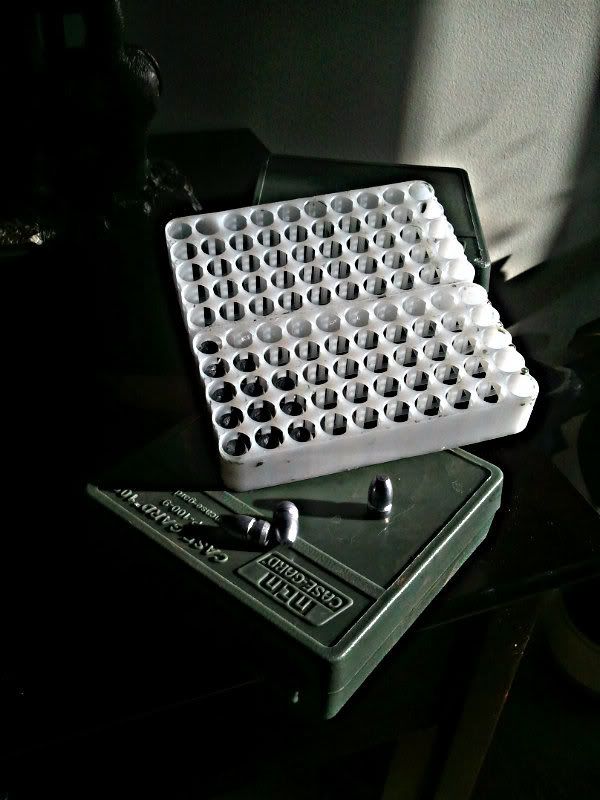

Edit: Here's a quick cellphone photo of the simple "tool" I use for putting the bullets in the pans. The bullets I mostly use for this method are the 9mm Lyman 356637 that drop just over .357 and ~156 grains as shown in the photo:

I just pick the trays out of the recycling boxes at the range and glue two together. Once they're filled with bullets, I place a pan upside down over it, then turn it all right-side-up, remove the tray, and voila - all neatly spaced and sitting in the pan ready for the lube to be poured in. Filling the plastic trays with bullets is the most time consuming part. But another reason why this method can be faster than using the lubrisizer is because I can recruit help to load up the bullet trays while I'm pushing bullets out of the removed lube that's already hardened. Sadly having extra help doesn't really make using a lube sizer go any faster.

I also use the Lee push-through sizer and tumble lube with LLA for certain bullets, like the Lee TL452-230-2R that work very well in my 1911s. I guess I too am an equal opportunity bullet caster and luber.