Quote:

What did I do wrong? I shot factory no prob. went home and reloaded 117 gr. spBT's same as factory. Took gun and MY ammo out hunting, didn't see a single deer, came home, and was unable to eject MY round out of the chamber. I was scared to keep it hot so I fired the round off and the case came out no prob. This happened a few times when I was out at the range. I would try taking out a live round out of the chamber and was unable to. I put a lot of pressure on the bolt, I'm telling ya, You would have needed a hammer... I always thought it was MY round being such a tight fit that it couldn't be taken back out....

Any ideas?

Going to reload again very soon. Thinking the same question. But a little skeptical of the Neck size only now!!!!!

|

I consider neck sizing or partial neck sizing to be sloppy reloading practices and your experience shows it.

I do not know why your cases come out after firing but I am of the belief that given enough neck sizing cycles, it will take a cleaning rod and a block of wood to get them out of the chamber. I think this will happen because of the inability of brass to spring back as much when it work hardens.

I full length resize everything, I use cartridge case headspace gages in setting up my dies, (I also headspace my rifles, most of them at least) and if the rifle headspace is between Go and No Go, then sizing to Gage minimum ensures that all cases will chamber without resistance. Also ensures that standard pressure loads extract without resistance.

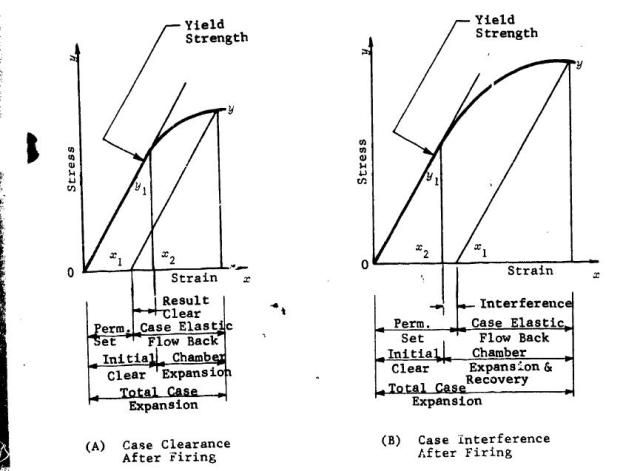

You can look at this image and see that both the chamber and case expand and contract during combustion. There is a tiny amount of springback in the brass and if the case did not over expand due to over pressure loads, there will be a clearance between the chamber and brass first firing. Second firing the brass will be a little harder and the clearance will be less. If the load is overpressure there will be an interference fit between the case and chamber. If you start out with an interference fit, such as people here are claiming is perfectly OK with neck sized rounds, then after firing, you will have even more of an interference fit.

As for case life, with my gaged chambers and gaged sized cases, I took one set of LC 308 cases 23 firings in match M1a’s. I lubricated the cases so I did not get any case head separations during extraction, dry cases will give about 8 to 10 loads before separating. I full length sized with small base die and bumped the shoulder back about 0.003” and got match winning accuracy out to 600 yards.

Safety and function are my highest priorities and I am skeptical about the supposed “accuracy” benefits of neck sizing. People who fuss over ¼” differences in group size when using a 300 lb concrete bench and 30 pounds of sandbags, and yet, get them off the bench they are unable to hold well enough to hit a refrigerator at 100 yards. These people wasting their time with esoteric reloading techniques, and if their ammunition jams in a hunting situation, they have wasted a lot more time and money.