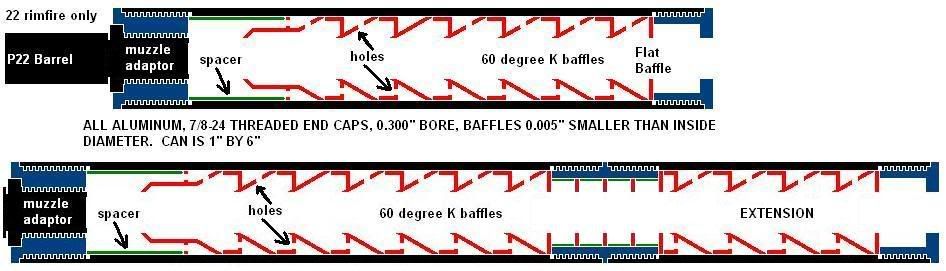

Here is a pic of a 22lr silencer. My final product rarely looks exactly like the drawing. I used a short simple 60 degree cone for the blast (first) baffle. It is a good idea to use steel for the blast baffle and reat end cap that screws onto the barrel for wear resistance. Aluminum is fine for all the other parts of a 22lr can unless you plan on using it on a machinegun, then it should be all steel.

A simple 60 degree conical baffle.

The M baffle is just a conical baffle with the spacer attached. I think they are harder to machine so I make mine with the spacer separate.

A step cone baffle. Should make more turbulence (a good thing) in the silencer.

Conical baffles are usually separated by spacers which are usually just thin pieces of tubing machined to just under the Silencer ID.

A K baffle, as it resembles the letter K. Usually used without spacers and will stay aligned to the bore even if it is not held in tight. It is not as strong as a conicl baffle of the same weight as the front flange can collapse under great stress. I only had this happen when hammering stuck baffles out of a dirty can for cleaning. The 0.050" thick 4130 K baffles I use in my 338 ultra mag are holding up fine.

Some parts of my last 22lr silencer. Shows the rear end cap with blast chamber spacer built in, a conical baffle, a step cone baffle, cone baffle, front end cap and a spanner wrench.

Ranb